With the proliferation of lithium production not only in the US but across the globe, Stardust Power is leveraging its network and strategic partnerships to source and produce battery-grade lithium domestically.

Stardust Power’s mission is to be committed to producing battery-grade lithium products while incorporating sustainability into each step of its process.

Their large-scale lithium refinery is now being optimised for multiple lithium brine outputs, which will help secure domestic, sustainable supplies for the US.

We spoke to Stardust Power to further understand the need for a domestic, sustainable supply of battery-grade lithium and how the refinery will help to meet these goals.

Why are domestic lithium production and refinery capacity in the US important? How is the US Government incentivising this?

The world needs more battery-grade lithium, especially America. Lithium is critical to powering America’s energy transition and this phase of global electrification.

With the global demand for lithium projected to soar, reaching nearly 3.5 million tonnes by the end of the decade, the US must strengthen its domestic production capabilities to meet its own needs and reduce dependency on imports.

The US currently does not produce nearly enough battery-grade lithium domestically. Thanks to early producers such as Albermarle and Livent, America produces approximately 20,000 tpa. However, we need more production.

Once completed, the Stardust Power refinery could satisfy up to 10% of the domestic lithium demand, making it a significant domestic manufacturer.

Additionally, domestic production promotes economic growth and job creation, stimulating local and national economies. It reduces trade deficits, strengthens domestic industries, and promotes ingenuity and technological advancement in the clean energy sector.

Our investment of over $1bn alone is expected to create hundreds of jobs. Moreover, producing lithium domestically aligns with sustainability goals, allowing for more stringent environmental regulations and ethical sourcing practices.

The US Government has been actively supporting the domestication of critical minerals production.

The DOE has issued billions of dollars of grants including the Bipartisan Infrastructure Law. Currently, they are allocating $3bn in this round.

The DOE LPO ATVM Program provides financing for projects that meet its criteria. Also, the Department of Defense has expanded its grant system for production through the Defense Production Act.

State governments have been doing their part as well. Stardust Power has an excellent relationship with the State of Oklahoma and has been provided with an analysis of incentives up to $257m.

How will Stardust Power’s battery-grade lithium refinery help realise the US’s supply chain security?

China currently dominates the lithium market with up to 85% refinery capacity. The US faces vulnerabilities in its critical minerals for sectors including defence and transportation. Rising geopolitical tension will increase Chinese protectionism.

Already, China has placed export restrictions on graphite, a key component of EV batteries. The US needs a secure supply chain of critical minerals, especially lithium, to maintain our economic, competitive edge and national security goals.

Stardust Power has developed a large-scale lithium refining capacity of American, IRA-compliant battery-grade lithium. Reducing its reliance on foreign sources of lithium, particularly in regions marked by geopolitical tensions, is a sizeable goal for the US.

Stardust Power is also sourcing the lithium feedstock from North America and potentially other FTA-compliant jurisdictions. By souring our feedstock from American markets and manufacturing domestically, we can present geopolitics from disruption to our supply chain.

How will Stardust Power work with oil and gas producers to address the US’s energy demands? Why is a partnership between the oil and gas industry and lithium refining essential?

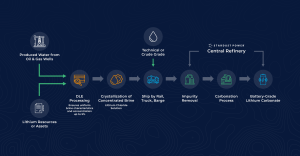

America has been producing lithium brines for decades. Oil & gas producers have been producing lithium-rich brines in certain areas as a byproduct of their production. In most cases, they have to pay for the disposal of this brine at significant costs.

Stardust Power can recycle this wastewater for the production of lithium chloride to be used as a feedstock for our battery grade products. We can create new lines of revenue in the energy transition for oil & gas producers. DLE can extract the lithium from the produced water.

Why is a diversified supply of lithium from US brine sources necessary?

The future of American lithium is in brine. Hard rock resources are notoriously hard to permit inside the US.

Hard rock assets typically entail large open pit mining techniques which have a significantly higher environmental and carbon footprint. Hard rock sources typically require high degrees of exothermic reactions to refine.

Our chemical conversion process does not require as much, so we can produce lithium brines responsibly and sustainably to power the energy transition.

Stardust Power’s technological innovation is optimising our central refinery for multiple sources of brine feedstock. By aggregating supply, we can scale production of battery-grade lithium products faster and more efficiently.

This approach also limits the risk of dependence on single assets.

What are the next steps for Stardust Power in 2024?

Stardust Power seeks to effectuate its merger with GPAC this summer. We aim to complete our definitive feasibility study by the end of the year early next year, and we will continue to aggregate feedstock opportunities.

We also will continue to be a proud supporter of resilient American supply chains through a collaborative and transparent process.

What is the anticipated annual production of high-quality battery-grade lithium?

The anticipated production of battery-grade lithium is 50,000 tonnes per annum. This will be achieved by developing two trains, each with a capacity of 25,000 tpa.

What considerations does Stardust Power give to sustainability?

Sustainability is built into each step of our process. We choose brine feedstock over hard rock to have a smaller carbon and environmental footprint.

We are designing our production trains as fully electric, we are designed for zero liquid waste discharge. We ever source power from largely sustainable sources such as wind and solar.

The batteries made from our products will power the energy transition.