Wayne Prokop and Mark Leonard from IMI Critical Engineering discuss how small modular reactors play a vital role in worldwide efforts to adopt sustainable energy policies.

In international energy markets, volatility is keenly felt. Global events over the last few years have underlined this. Firstly, the disruption and the subsequent swift economic recovery from the pandemic, and second, the lasting impact of Russia’s invasion of Ukraine.

The sanctions placed on the country’s huge natural gas reserves continue to affect energy prices today. European states have had to adapt their supply lines to improve their country’s overall resilience, with many previously mothballed coal plants brought back online for contingency power purposes.1

While bringing these previously shut-down plants back online to meet peak demand during the colder months was practical, it has understandably sparked debate.2 Considering ongoing decarbonisation efforts, some have questioned whether other technologies are better suited to provide contingency power.

Small modular reactors (SMR) have grown in popularity as a potential sustainable energy solution. Yet the technology’s rollout remains in its infancy when compared to legacy assets, including coal power plants. Given this, and the pressing need to enhance energy security across Europe, a more considered approach will be required to adopt SMRs at scale and phase out fossil fuel-based power provision.

Adapting existing coal plants into small modular reactors

It is understandable why some think coal is making a comeback, but overall trends show that this is not the case, and sustainable energy initiatives are moving forward.

Coal’s share of domestic electricity generation in the US dropped to record lows for Q1 20233, and existing plants are proving more expensive to supply and maintain compared to the ‘all-in’ costs of new wind and solar projects.4

These are clearly not signs that point to a coal-powered renaissance. Still, cautiousness is required when completely removing it from national energy mixes, especially with many countries still using coal to offset volatile power markets.

Sustainable energy solutions are still subject to intermittency issues, even if more cost-effective energy storage solutions are being developed. As such, it is reasonable to assume that coal will still have a presence in some nations’ power grids in the immediate future.

Coal’s role as an expensive but necessary means to manage short-term peaks means attention must be paid to the infrastructure supporting it. Its use as contingency hinges on whether small modular reactors can respond to real-time demand changes, yet this is not something for which they were traditionally designed. Mismanaging rapid synchronisation could lead to problems beyond strained grid capacity alone.

Issues of this kind are already apparent within gas-fired combined cycle power plants (CCPPs). Intermittency concerns from phasing in more renewable energy sources are causing current CCPPs to cycle more often, providing varying power to fill gaps based on grid demand changes. Operational stresses are now becoming increasingly apparent as facilities designed for continuous operations are forced to stop and restart, with loads fluctuating between 50% and 100%.

During this type of operation, issues like valve degradation and cracks in pressure boundaries are becoming more frequent. This is especially true in areas where water is injected into the steam flow to control temperature, as well as in turbine bypass systems and interstage attemperators.

However, these areas are easily overlooked when compared to components that constitute greater amounts of overall plant expenditure – for example, the steam turbine. Yet, if not accounted for, these smaller components can seriously affect a plant’s ability to remain functional and swiftly respond when called upon, hampering the CCPP’s effectiveness as a contingency solution.

Making a success of succession

The impact of a well-devised maintenance strategy goes beyond contingency – they are also vital to the succession plans of coal-fired power plants, especially where small modular reactors are concerned.

As the International Energy Agency notes, by repurposing old fossil plants with these reactors, local customers can access abundant power without the upheaval associated with major changes to existing infrastructure. This is afforded by a similar output between 200Mwe and 400Mwe, allowing SMRs to effectively ‘slot in’ to old grid connections.

Compared to the extensive costs and timescales associated with large-scale nuclear facilities, the appeal of this smaller easier-to-implement technology is clear.5

Alongside convenience, this repurposing process also provides logistical benefits. Namely, issues around finding a sufficient water source, establishing road and rail links and sourcing a nearby skilled workforce have already been addressed, and there is no need to acquire additional land.

Though great strides are being made toward fully commercialising the technology, SMRs are still in a nascent stage of development. Currently, 70 provisional designs are in consultation across 18 countries, and standardisation and best practice is still being defined.6

Engaging suppliers specialising in nuclear technology will therefore be key to proving the practical merits of SMR technologies and going beyond the concept stage.

The ball is already rolling on the adoption of small modular reactors. For instance, Rolls-Royce recently secured government funding to build a fleet of 470MW reactors that will be up and running by the early 2030s.7 Though this is still around ten years away, organisations with expertise in the industry are accelerating adoption, with IMI Critical Engineering assisting in the design and application of critical components.

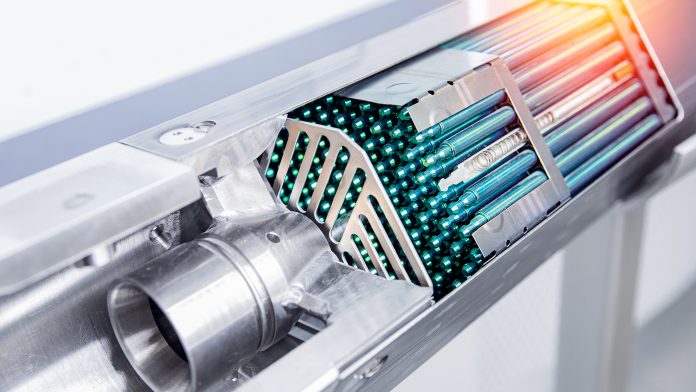

Though the organisation’s main steam safety valves, emergency core cooling system strainers and main steam isolation valves may be comparatively small features within a plant’s overall design, they are essential to ensuring an SMR functions safely and optimally.

It must also be noted that long regulatory approval processes are a fact of life in this sector. Even for businesses that are ahead of the curve and looking to innovate, standardised, clearly proven technologies will remain attractive.

Similarly, if the power industry is to push ahead with its ambitious decarbonisation plans, the need for familiar solutions will only become more acute. This is also to say nothing of the hesitance some may feel at the rapid adoption of nuclear power generation technologies. In these circumstances, implementing valves and components that have already been shown to work will be vital to assuaging very valid concerns.

Critical service knowledge and fossil fuel phaseout plans are closely linked. To ensure coal plants are incorporated into decarbonisation efforts, using already-existing infrastructure will be key, especially with costs remaining one of nuclear’s biggest barriers to adoption.8

This sentiment of making do with what we have can also be extended to the development of SMRs as a means of transitioning from coal. As the nuclear sector has traditionally struggled with construction delays and spiralling costs on new buildings, partly because of overengineering, adapting existing infrastructure may hold unique appeal.9

Taken in isolation, valve components cannot solve our pressing and future energy concerns. However, the vital role they will have in the short-, medium- and long-term of the energy transition means they cannot be overlooked.

Wayne Prokop is Global Sales Director and Mark Leonard is Business Development Director for IMI Critical Engineering, for more information, visit: https://www.imi-critical.com/industry/nuclear/

References

- https://www.lemonde.fr/en/economy/article/2022/09/02/despite-climate-commitments-the-eu-is-going-back-to-coal_5995594_19.html

- https://www.theguardian.com/business/2023/mar/07/national-grid-power-plants-coldest-night-of-year-extra-electricity

- https://ieefa.org/resources/us-coal-generation-falls-record-first-quarter-low

- https://energyinnovation.org/publication/the-coal-cost-crossover-2021/

- https://www.iaea.org/newscenter/news/repurposing-fossil-fuel-power-plant-sites-with-smrs-to-ease-clean-energy-transition

- https://www.iaea.org/newscenter/news/accelerating-smr-deployment-new-iaea-initiative-on-regulatory-and-industrial-harmonization

- https://www.ft.com/content/b2cf6c9b-7a3e-4e95-b1bf-428ad8b1d7c3?sharetype=blocked

- https://thebulletin.org/2019/06/why-nuclear-power-plants-cost-so-much-and-what-can-be-done-about-it/

- https://www.raconteur.net/sponsored/realising-the-uks-nuclear-renaissance