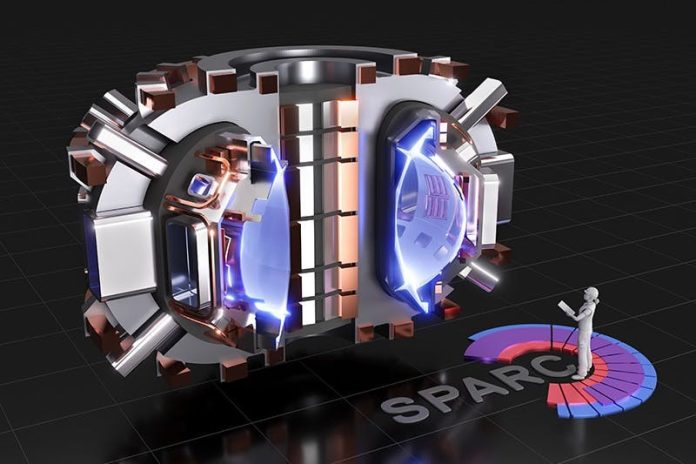

The race to harness fusion energy as a clean, limitless power source is accelerating, and the SPARC fusion reactor is at the forefront of this revolutionary quest.

A crucial breakthrough in plasma cooling has been achieved through an advanced gas injection system designed to prevent disruptions and optimise SPARC reactor efficiency.

Researchers from Commonwealth Fusion Systems (CFS), in collaboration with experts from the United States Department of Energy’s Princeton Plasma Physics Laboratory (PPPL), the Massachusetts Institute of Technology (MIT), and General Atomics, have fine-tuned this technology using high-precision simulations.

Their work ensures that SPARC can manage extreme temperatures while pushing fusion energy closer to commercialisation.

Controlling plasma at extreme temperatures

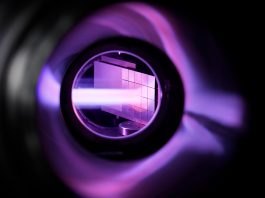

Fusion reactors like SPARC operate at temperatures hotter than the Sun’s core, making it essential to manage plasma behaviour effectively.

Disruptions in the plasma can lead to jets of superheated particles striking the inner walls of the reactor, potentially damaging critical components.

To mitigate this risk, researchers have developed a system that rapidly injects cooling gas to dissipate excess heat and stabilise the plasma.

However, the challenge lies in finding the precise number and placement of gas valves to maximise efficiency without compromising reactor space.

Advanced simulations unlock the optimal gas injection design

To tackle this problem, the research team turned to M3D-C1, a sophisticated computational code developed at PPPL.

This powerful simulation tool enabled scientists to model various gas injection configurations, analysing their effectiveness in mitigating plasma disruptions.

The results revealed that an arrangement of six gas valves – three at the top and three at the bottom of the fusion vessel – provides the best balance between cooling efficiency and spatial optimisation.

Precision cooling for sustainable fusion energy

The SPARC fusion reactor utilises powerful magnetic fields to confine plasma in a toroidal, or doughnut-shaped, configuration.

As an experimental prototype, SPARC is designed to refine key technologies that will pave the way for commercial fusion energy production.

A major hurdle in this effort is ensuring that disruptions can be managed efficiently, allowing the reactor to restart quickly after a shutdown.

The new gas injection system plays a critical role in achieving this goal. By injecting cooling gas through strategically placed valves, the system prevents excessive heat from damaging the reactor walls.

This is especially crucial for high-magnetic-field fusion devices like SPARC, where the risk of plasma instabilities is higher.

Cutting-edge computational techniques enhance simulation accuracy

The development of the SPARC gas injection system marks one of the most comprehensive disruption simulations ever conducted in fusion research.

The team evaluated multiple configurations, including symmetric and asymmetric valve placements, using high-performance computing resources.

Each simulation required weeks of processing time, demonstrating the complexity of modelling plasma behaviour in real-world conditions.

A key advancement in these simulations was the implementation of non-equidistant meshing. Traditional simulations divide the fusion reactor into uniform slices, but this approach can struggle to capture fine details.

By applying non-equidistant meshing, researchers were able to allocate more computational resolution to critical areas – such as the immediate vicinity of the gas valves – while maintaining overall efficiency. This breakthrough significantly improved the accuracy of plasma behaviour predictions.

Public-private collaboration drives fusion innovation

The success of this research underscores the importance of collaboration between public institutions and private companies in the race to develop fusion energy.

PPPL’s expertise in advanced computational modelling was instrumental in optimising the SPARC design, while CFS contributed its cutting-edge engineering capabilities.

This synergy between government-funded laboratories and private industry accelerates the development of practical fusion solutions.

Beyond SPARC, these advancements will also influence the design of future fusion power plants, including CFS’s planned ARC power plant in Chesterfield County, Virginia.

By refining plasma control mechanisms, researchers are making tangible progress toward achieving commercially viable fusion energy.

The future of SPARC and fusion energy

The breakthroughs in gas injection technology bring fusion energy one step closer to reality. As the SPARC fusion reactor continues to evolve, the insights gained from these simulations will contribute to the refinement of next-generation fusion reactors.

With continued advancements in plasma stabilisation and disruption mitigation, fusion energy holds the potential to provide a virtually limitless and carbon-free power source for the world.

By pushing the boundaries of scientific research and fostering strong partnerships, SPARC is laying the foundation for a future powered by clean and sustainable fusion energy.