The development of the large-scale biotechnological production of spider silk proteins in the last two decades has enabled new applications biomaterials.

Spiders have evolved silks which uniquely combine tensile strength and extensibility, making it the toughest natural fibre material on Earth, even surpassing man-made materials such as polyamides, polyaramids or other performance fibres. In contrast to those plastic materials, spider silk is a green polymer consisting of almost 100% proteins which are fully biodegradable. Therefore, the benefits of spider silks are manifold. To date, a myriad of possible uses for spider silk have been proposed, from medical applications to the incorporation in textiles.

Silk has been utilised by humankind for millennia, and biomedical applications in particular have always been a central focus. Spider webs were used in ancient times by the Greeks and Romans to stop wounds from bleeding, and trials with spider silk fibres as sutures go back to the 18th century. A major drawback in the past, however, has been low producibility, partly based on the cannibalism of most spiders, which makes the natural scale-up of production using spiders unfeasible.

A breakthrough was the establishment of a scalable biotechnological process enabling the production of recombinant silk derived proteins by our group in 2004.1 The biotech process enables for the first time the scale-up of the production of such proteins at constant high quality and yield. Four years after publishing the first patents and research papers, the spin-off company AMSilk GmbH (Martinsried, Germany) was launched in 2008, with the aim to scale-up production to industrial scale and develop products for the market at attractive prices.

The innovative technology developed in our group together with the scaling and application expertise at AMSilk brought new products to the markets which – apart from the outstanding properties of the material – might pose a solution to one of the biggest challenges of our time: reducing the plastic waste and environmental burden of common crude-oil derived products via sustainable and biodegradable performance biogenic materials.

Processing silk proteins: biomimetic spider silk fibres

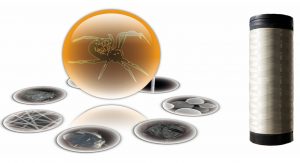

The biomaterials group at the University of Bayreuth processes recombinant spider silk proteins into a huge variety of morphologies including particles, foams, films, hydrogels, and non-woven mats, amongst others (see Fig. 1, left). One of the most important processing breakthroughs was the first production of a man-made spider silk fibre with a toughness indistinguishable to that of the natural blueprint.2 Based on that groundbreaking spider silk technology, the commercial fibre Biosteel® was developed by AMSilk GmbH (see Fig. 1, right), which is already available on the market in textile products such as watch straps. In this article, the focus will, however, be on the biomedical applications of spider silk-based materials.

Biomedical applications of silk: drug delivery systems

Drug delivery systems are one of the most intensively investigated biomedical applications of materials made from recombinant spider silk proteins.3 Due to the different possible morphologies, spider silk-based materials can be used both as stationary and mobile drug delivery systems. Particles and thin-walled capsules are well suited for the latter. Upon genetic modification of the recombinant spider silk protein, cell targeting sequences can be implemented to be exposed on the surface of the delivery system enabling a cell/tissue specific drug delivery. In contrast, hydrogels as well as film coatings have been successfully tested as stationary drug depots, from which controlled release of low as well as high molecular weight drugs and biologicals can be realised.

Biomedical applications of silk: implant coatings

Upon implantation, a common biomaterial’s surface causes distinct body responses triggered by adsorbed proteins followed by monocyte and/or macrophage adhesion. Depending on the biomaterial, severe side reactions such as inflammation or scar formation can be the result. Spider silk has been shown to be highly compatible with the human body, i.e. no or only little immune reaction has so far been identified, which lowers the risk of inflammation and/or later allergic responses towards spider silk-based materials. The lack of an immune response towards several tested spider silk materials is not fully understood, but it could be shown that spider silk materials, such as coatings or 3D-printed hydrogels, prevent infestation of pathogens such as bacteria and fungi.

This lack of cell adhesiveness might be one reason for the ‘stealth mode’ of spider silk surfaces inside the human body. One can use this property to mask established products, such as catheters or silicone breast implants by coating them with spider silk (Fig. 2 left).4 The latter are currently in a clinical study to reach regulatory approval.

Biomedical applications of silk: biofabrication

Biofabrication is an additive manufacturing technology allowing the combination of living cells with biomaterials serving as bioinks (mainly hydrogels) in order to generate hierarchical tissue-like structures. It has been shown that spider silk hydrogels show several beneficial properties to be used as a bioink material, namely cell compatibility, adjustable mechanical properties in the regime of living tissues, shear thinning behaviour enabling dispense blotting (Fig. 2 right), and a fast regeneration of its shape through biophysical crosslinking (which allows to omit additives such as cross-linkers or plasticisers otherwise often necessary for 3D printing). Currently, several approaches focus on the regeneration of peripheral nerves or heart muscle tissue based on recombinant spider silk based bioinks and materials.

Next steps towards silk-based materials in biomedicine

Spider silk has been shown to allow angiogenesis without triggering inflammation, which is a benefit in terms of wound healing. Furthermore, the biodegradability of spider silk enables a spider silk scaffold to be replaced with a new body-made tissue, while the byproducts of degradation, namely amino acids, are non-toxic to the body and can be easily removed. Since biodegradation is slow, the mechanical properties of spider silk-based implants are maintained for a period lasting from weeks to months, which is advantageous in several biomedical applications.

Silk-based materials are, therefore, very well suited for clinical applications as drug delivery systems or implant coatings, as already shown, but also as artificial grafts for ligaments, nerve, bone, skin, and muscle, amongst others.

The necessary next steps for their commercialisation are clinical trials to obtain regulatory approval. Therefore, we have started selected preclinical studies in order to gain more insights into the biological integration and the functionality of spider silk-based materials within the human body and to pave the way for future applications.

References

- Huemmerich, D.; Helsen, C.W.; Oschmann, J.; Rudolph, R.; Scheibel, T. (2004). ‘Primary structure elements of dragline silks and their contribution to protein solubility and assembly’. Biochemistry 43, 13604-13612

- Heidebrecht, A., Eisoldt, L., Diehl, J., Schmidt, A., Geffers, M., Lang, G., Scheibel, T. (2015) ‘Biomimetic Fibres Made of Recombinant Spidroins with the Same Toughness as Natural Spider Silk’. Advanced Materials, 27, 2189–2194

- Aigner, T.B., DeSimone, E., Scheibel T. (2018) ‘Biomedical applications of recombinant silk-based materials’ Advanced Materials 30, 1704636

- Zeplin, P.H., Maksimovikj, N.C., Jordan, M.C., Nickel, J., Lang, G., Leimer, A.H., Römer, L., Scheibel, T. (2014) ‘Spider silk coatings as a bioshield to reduce periprosthetic fibrous capsule formation’. Adv. Funct. Mat., 24, 2658-2666

Thomas Scheibel

Head of Biomaterials and Vice President

University of Bayreuth

+49 921 556701

thomas.scheibel@bm.uni-bayreuth.de

www.fiberlab.de

Please note, this article will also appear in the second edition of our new quarterly publication.