SPINTEC in Grenoble has proposed and demonstrated a new concept of magnetic memory thermally stable and electrically switchable at diameters down to 4nm.

Positioned at the crossroad of science and technology, SPINTEC (SPINtronics and TEchnology of components) is one of the leading spintronics research laboratories worldwide. Spinelectronics is a merging of magnetism and microelectronics. It aims at using the spin of the electrons in addition to their charge to reveal new phenomena and use them to improve the performances of microelectronics devices (especially to reduce their power consumption) or to create new functionalitites such as the newly demonstrated concept of magnetic memory.

Ideally located on the MINATEC campus in Grenoble, SPINTEC gathers, in a flexible and project-oriented organisation, physicists and engineers from the academic and industrial worlds. The laboratory was created in 2002 and rapidly expanded to currently reach 100 persons, including 41 Permanent staff and about 50 PhD students, post-docs and international visitors. The scientific institutions taking part in the lab are: CEA, CNRS and Univ. Grenoble Alpes (UGA).

SPINTEC‘s objective is to bridge fundamental research and innovative devices technology in the field of spin electronics (spintronics). The international technology roadmap for semiconductors (ITRS) now believes that spintronics devices will play a major role in tomorrow’s semiconductor chips. As a matter of fact, a new type of magnetic memory called ‘Spin Transfer Torque Magnetic Random Access Memory’ (STT-MRAM) is entering volume production at major microelectronics foundries such as Samsung, TSMC, and Global Foundries. Now that this hybrid CMOS (Complementary Metal Oxide Semiconductor)/magnetic technology is accepted by the microelectronics industry, an exponential growth of spintronics applications and products can be envisioned, in particular for low power electronics (wearable electronics, Internet of Things, and consumer electronics, as well as high performance computing).

Other fast-developing fields include magnetic field sensors and bio-applications.

A unique position

Spintec’s unique positioning brings together top-level scientists and applicative engineers that work in close collaboration in order to ensure that new paradigms can be swiftly translated into technology proof of concepts and functional devices. As such, the outcome of the laboratory is not only scientific publications and communications in international conferences, but also a coherent patents portfolio and implementation of relevant functional demonstrators.

While the fundamental research is mostly operated through collaborative (financed) projects with other research laboratories (in particular UMϕ CNRS/Thales in Palaiseau and Institut Jean Lamour in Nancy), the applied research is very often carried out in partnership with private actors. These can be large corporations (Applied Materials, STMicroelectronics, Thales, Samsung, Seagate, and so on), SMEs (SNR, Singulus etc.) or start-ups (Crocus, Menta, Spin Transfer Technologies, Evaderis, Antaios, Hprobe and more). Spintec has already spun-off four start-up companies, Crocus Technology, in 2006, eVaderis in 2014, HProbe and Antaïos in 2017.

SPINTEC: key contributions to developing a magnetic memory

Non-volatile memories designate memories which have the capability to retain the stored information even when they are not electrically powered. This is the case of FLASH memories used in Solid State Drives or USB keys. In contrast, memories such as DRAM or SRAM which constitute the working memories in computers are volatile, in that they cannot keep their information if they are not electrically powered.

Various technologies for non-volatile memories exist based on ferroelectric materials (FeRAM), phase change materials (PCRAM), resistive oxides (ReRAM) or magnetic materials (MRAM) and particularly those written by spin transfer (STT-MRAM). Among them, STT-MRAM gathers a unique combination of assets: write speed (3-30ns), density (4Gbit demonstrated by Hynix/Toshiba), low consumption (a few tens of fJ/write), and, very importantly, an extremely long write endurance (>1013 write cycles for write durations>30ns).

Conventional STT-MRAM are based on out-of-plane magnetised magnetic tunnel junctions (MTJs) in which the storage layer magnetisation is pulled out-of-plane thanks to a perpendicular anisotropy originating from the interface between the oxide barrier and the magnetic electrodes. This phenomenon was discovered at SPINTEC in 2002. This breakthrough allowed the combination of high magnetic anisotropy providing long memory retention with low write current, two properties a priori very difficult to conciliate (see Rev. Mod. Phys. 89, 025008 (2017)). All magnetic tunnel junctions implemented in forthcoming STT-MRAM products will use this interfacial anisotropy phenomenon.

spin-orbit-torque

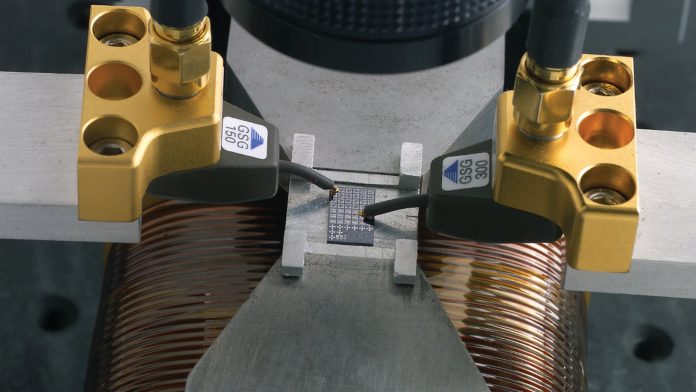

Another breakthrough discovery made at SPINTEC in 2011 has been the possibility to write in a magnetic memory by a current flowing underneath the magnetic tunnel junction using a phenomenon called spin-orbit-torque (SOT-MRAM). This contrasts with conventional STT-MRAM which are written by a current flowing vertically through the stack. In SOT-MRAM, since the write current does not traverse the magnetic tunnel junctions, their write endurance (i.e. the possible number of write cycles) is significantly increased as compared to STT-MRAM. This is especially important for fast memory applications such as SRAM which have cycle times of the order of a few nanoseconds.

SPINTEC is also very active in bridging the cultural gap between the microelectronics and magnetics communities through various initiatives such as the annual Introductory Course on MRAM (InMRAM, www.inmram.com) or the MRAM poster session and MRAM Global Innovation Forum organised at each IEDM conference (which is the main annual conference of the IEEE Electron Devices Society). Reducing this cultural gap is very important for the development of this hybrid CMOS/magnetic technology which requires joint efforts from experts in microelectronics and in magnetism.

Introducing the concept of perpendicular shape anisotropy magnetic memory

To increase the STT-MRAM downsize scalability, a novel type of MRAM with much thicker storage was proposed and developed at SPINTEC. By drastically increasing the thickness of the storage layer to values comparable to its diameter, a perpendicular shape anisotropy (PSA) is induced in the storage layer which comes on top of the previously mentioned interfacial anisotropy with no penalty on the switching current. As a result, the perpendicular anisotropy is greatly reinforced, enabling the magnetic thermal stability (i.e. good memory retention) to be maintained down to a diameter of the order of 4nm. The name PSA-STT-MRAM was coined to designate this memory.

In addition to their excellent and tunable thermal stability at sub-10nm diameter, PSA-STT-MRAM have additional advantages, such as the fact that bulk and interfacial properties of the storage layer can be separately optimised. For instance, low Gilbert damping material can be used in the bulk of the storage layer to reduce the write current without compromising on the tunnel magnetoresistance amplitude. Furthermore, because the storage layer is thick, the thermal variation of its magnetic properties is much closer to that of the corresponding bulk material and therefore much less temperature dependent than when very thin storage layers are used. As a result, PSA-STT-MRAM can more easily be designed to operate on a wide range of temperature than conventional STT-MRAM. This is very important for automotive and industrial applications or to fulfill solder reflow compliance.

In conclusion, STT-MRAM are entering in volume production. This marks the acceptance of this new technology by microelectronics industry.

PSA-STT-MRAM already offers a perspective of downsize scalability to sub-10nm nodes. This is just the beginning of spintronics applications in microelectronics. Lot of new materials and phenomena are being studied in research lab such as SPINTEC to prepare the following steps.

Acknowledgement: Work supported by ERC Adv.Grant MAGICAL n°669204

Bernard Dieny

Devices Group

SPINTEC

+33 4 3878 3870

bernard.dieny@cea.fr

http://www.spintec.fr/