As the world moves toward sustainable, energy-efficient solutions, a groundbreaking innovation in battery technology is set to transform everything from electric cars to mobile devices.

Picture a future where vehicles are lighter, laptops are thinner, and mobile phones are as slim as credit cards—without sacrificing performance. This vision is becoming a reality thanks to structural batteries, a cutting-edge technology that combines energy storage with structural support.

This breakthrough promises longer ranges for electric vehicles (EVs), extended battery life for consumer electronics, and reduced energy consumption across industries.

A research team at Chalmers University of Technology in Sweden is at the forefront of developing this revolutionary technology. But what exactly is a structural battery, and how could it change the future of energy storage?

What is a structural battery?

A structural battery is a next-generation technology that integrates a battery’s energy-storing function with a load-bearing structure.

This dual-purpose material not only powers devices but also provides physical support. By reducing the overall weight of a product, structural batteries enhance energy efficiency, particularly in vehicles, aircraft, and electronic devices.

For instance, incorporating structural batteries into EVs could increase driving range by up to 70% while making laptops lighter and mobile phones as slim as a credit card.

At the forefront of this field, Chalmers University researchers are pushing the boundaries of structural battery development, aiming to revolutionise how we store and use energy.

Pioneering massless energy storage

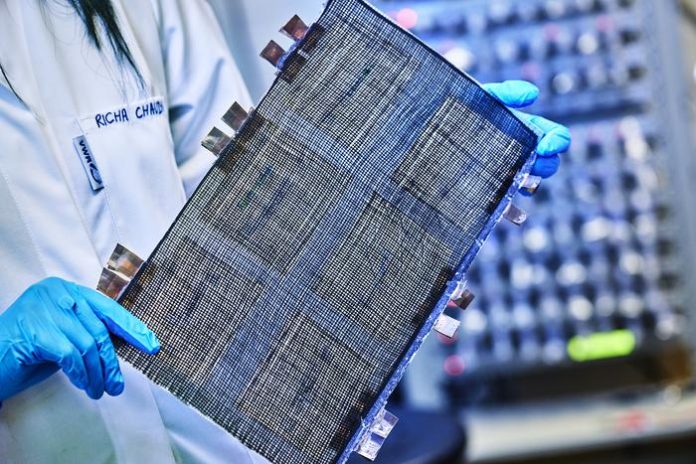

The research team at Chalmers has developed a carbon-fibre-based structural battery that is as strong as aluminium and energy-dense enough to compete with traditional batteries.

As Richa Chaudhary, lead author of the research, explains, the new battery functions similarly to a human skeleton, providing both support and power. This development represents a significant advance in ‘massless energy storage’—where energy storage is seamlessly integrated into the material used for a product’s structure.

Chalmers has been working on structural batteries for years, and recent breakthroughs in energy density and material stiffness mark major steps toward commercial use.

Since discovering in 2018 that stiff carbon fibres could store energy, the research team has made impressive progress, creating a lighter, more powerful battery than ever before.

The science behind structural batteries

The batteries developed by Chalmers use composite materials, with carbon fibre serving as both the positive and negative electrodes.

Lithium iron phosphate is applied to the carbon fibre in the positive electrode, while the negative electrode acts as both an energy storage material and structural reinforcement.

This multifunctional design eliminates the need for traditional heavy current collectors like aluminium and copper, further reducing the battery’s overall weight.

Additionally, the design avoids using conflict metals like cobalt, making the technology more sustainable. The semi-solid electrolyte used in the battery enhances safety by reducing the risk of fire, although further research is needed to achieve high power output for commercial applications.

Lighter vehicles, lower energy use

One of the most exciting applications of structural batteries is in the automotive and aerospace industries, where reducing vehicle weight can significantly improve energy efficiency.

The new batteries, with an energy density of 30 watt-hours per kilogram (Wh/kg), could allow electric vehicles to travel up to 70% farther on a single charge.

While this energy density is slightly lower than current lithium-ion batteries, the weight reduction achieved through structural integration offsets this, leading to overall better performance.

Additionally, the stiffness of the battery materials has greatly improved, from 25 to 70 gigapascals (GPa), making the structural batteries both lightweight and strong enough to meet safety standards for vehicles and aircraft.

According to Leif Asp, the research team’s leader, these advancements pave the way for more efficient transportation, making lighter, longer-lasting electric cars more feasible.

Moving towards commercialisation

Despite the promise of structural batteries, the path to commercialisation is complex. To help bridge this gap, Chalmers has launched a spin-off company, Sinonus AB, to scale up production and bring the technology to market.

The goal is to integrate structural batteries into consumer electronics and transport systems in the near future.

Professor Asp envisions a world where mobile phones and laptops are thinner, lighter, and more durable thanks to this innovation.

The automotive and aerospace industries have already shown great interest in structural batteries, highlighting their potential to revolutionise these sectors.

However, challenges remain, including improving energy density, optimising electrolyte performance, and scaling up production.

Despite these hurdles, Asp is optimistic that structural batteries will soon reshape how we think about energy storage and material design.

The future of structural batteries

As structural battery technology advances, its potential applications are vast. From lightweight EVs to ultra-thin consumer electronics, this technology could reshape industries that rely on both power and structural integrity.

While widespread commercialisation may still be a few years away, the rapid progress in this field suggests that structural batteries are poised to become a key player in the future of energy storage.