Lars Georg Backer, CEO of Flatsetsund Engineering AS, outlines how its sustainable delousing solution is both cost effective and environmentally friendly.

Salmon farming is a growing industry with a strong focus on increased production, biomass, and quality. With high growth and a larger number of fish gathered in smaller areas, it is important to be able to control fish health and welfare. The aquaculture industry must focus on sustainability and animal welfare solutions to achieve its growth goals.

One of the most significant challenges for the salmon industry is sea lice and its consequences for fish health, fish quality, and economy. The industry must meet this problem efficiently and sustainably and control the salmon’s sea lice levels.

Flatsetsund Engineering (FLS) has now been developing equipment for the aquaculture industry for some 30 years – always with a sharp focus on fish welfare and sustainable solutions. The FLS Delouser is a result of more than 10 years of innovative development. It has been tested and approved by major companies within the fish farming industry and by the Norwegian Food Safety Authority, being recognised for taking care of fish welfare exceptionally well.

An all-natural, chemical-free treatment

Parasite control has been an increasing challenge for salmon and trout farming with the growth of biomass. It is now one of the most significant challenges being faced by the industry. Various chemical treatments have been – and in some areas still are – the most common methods. This has, at best, an uncertain impact on the environment.

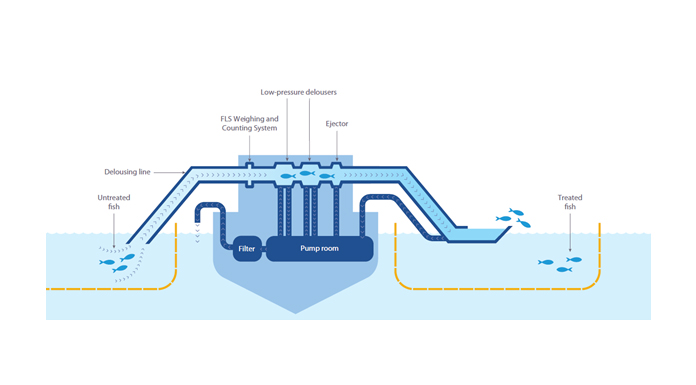

The FLS delousing technology is all-natural. It is a mechanical low-pressure flushing method using seawater at seawater temperatures. There are neither any chemicals involved nor any use of energy for heating the water.

Table 1 shows the given number of prescriptions for active substances for chemical treatment and the number of weeks of reported treatment for the other methods (Source: the Norwegian Veterinary Institute, ‘Annual Fish Health Report’).

Effective and sustainable delousing

Any handling of the fish is detrimental to their welfare and so should be done as infrequently as possible. The FLS Delouser can achieve the highly effective removal of sea lice on a degree of 95% and more. These numbers are, of course, depending on the fish’s general health at the moment of treatment, the size of the fish, the performance of the whole operation, and other situational factors, but it has nevertheless still proven extremely efficient.

One of the important and unique qualities of the FLS Delouser is our innovative flushers. Firstly, our flusher is a full water flusher – we understand that it is certainly not good for the fish to be dried up – even for a short period of time. Secondly, you need a certain pressure to remove sea lice. We know that the effect of flushing in full water is complicated, because the distance from the flusher walls to the fish cannot be too far. After years of innovation, our flushers are now highly effective low-pressure flushers, needing a pumping pressure of just 0.65–0.85 bar.

Our pipelines are perfectly dimensioned to our low pressured flushers in order to carefully handle all sizes of salmon.

Gentle handling with focus on fish welfare

The salmon is a fragile muscle bundle, and so must be treated with care. Congestion and pumping have a substantial effect on the fish. This must be done as gently as possible to achieve low mortality rates and a low number of wounds and injuries.

FLS has documented high welfare results for the FLS Delouser in a report from the veterinary institute Inaq in 2018. This report also led to a conclusion from the Norwegian Food Safety Authority.

Pumping pressure is, of course, an important factor to consider in terms of fish welfare. The FLS Delouser works like a siphon, collecting the fish at sea level and delivering them back in the cage at sea level, with a vacuumed system in between. This results in zero lifting heights. We use an ejector to move the water (and fish) through the delouser, and because of the zero lifting height, we are able to use a pumping pressure of just 0.35-0.45 bar, just a fraction of the pressure required by all other systems for lifting fish onboard a vessel for delousing. This is very important for fish welfare and, of course, reduces the operation’s energy consumption.

Because the FLS Delousing system ensures that the treated fish are delivered into the cage at sea level, the fish are always completely submerged during the treatment, which is always in full water, meaning that their welfare is being looked after. Indeed, the fish are not exposed to the atmosphere for more than a fraction of a second and, moreover, are not exposed to weather and climate conditions.

Energy consumption

For FLS, sustainability not only focuses on fish welfare, but also on the surrounding environment and on energy consumption. Due to our low-pressure washers and the siphon with zero lifting heights, the operation’s energy consumption is less than with comparable methods. Moreover, the method does not use heated water, which is also energy-intensive.

During the delousing process, many sea lice will be in the water, going through the delousing lines together with the fish. It is important to collect all of this water for filtration in order to reduce the risk of reinfecting the newly-cleaned fish. In the FLS Delousing system, all the process water is collected and pumped onboard the vessel for filtration.

A profitable solution

Removing sea lice is not overly difficult; the challenge is to combine effective treatment, safeguard fish welfare, and reduce environmental impacts. There is an increasing focus on fish welfare in the aquaculture industry, but this runs in tandem with a focus on profitability and efficiency for both the fish farming companies and the service companies that carry out delousing. FLS welcomes this growing trend, as sustainable solutions, fish welfare and profitability for the industry have always been our focus.

There are essentially two elements to a profitable solution; the impact on the fish, and the cost of the operation. We can document that the FLS Delouser has a very low mortality rate (down to 0.1%) and that the salmon have a low stress level (so much so that they consume food immediately after the operation). Thus, the loss of biomass is minimal as a result of the delousing process, which is an important parameter for breeders.

Please note, this article will also appear in the fifth edition of our quarterly publication.