To achieve a circular plastics industry, no ‘one-size-fits-all’ solution will do, but a combination of different approaches will be required.

In 2022, 400.3 Mt of plastics were produced worldwide (Source: Plastics Europe). Unsurprisingly, consumers and legislative authorities are demanding change and more careful use of resources to achieve a plastics industry that is as climate-neutral as possible. The Institute for Materials Technology and Plastics Processing (IWK, part of OST-Eastern Switzerland University of Applied Sciences) is working on contributing to this goal.

The competence spectrum of the IWK is divided into the following eight research fields: Injection Moulding/PUR, Compounding/Extrusion, Composite Technology/Lightweight Construction, Joining Technology, Metal Manufacturing Technologies, 3D-printing/Additive Manufacturing, Simulation & Design, and Material Analysis & Component Testing.

The ambition for all the competence areas is to combine science and practice for innovative industrial-oriented, close-to-production solutions and, through that, address the current challenges of the plastics industry with optimised materials, material combinations and production technologies.

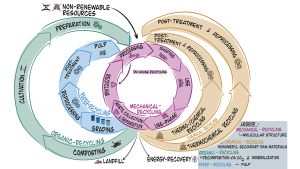

Alongside reduction and reuse, recycling is one of the most important strategies for achieving the goal of a circular and sustainable plastics economy. The Compounding and Extrusion team at the IWK, led by Professor Daniel Schwendemann, focuses on a holistic approach to identifying the most suitable pathway for circularity for each customer-specific application. In the upcoming paragraphs, some exemplary projects are presented. Each of them explores a different recycling route based on the following graphic.

Mechanical recycling – Is it possible to close the loop or even upcycle?

Mechanical recycling is a well-established process in the plastics industry in which products at their end of life are collected, cleaned, sorted, and converted into new raw materials again. While the ideal scenario would be a cradle-to-cradle material flow or even an upcycling of the used material, for most of the applications, mechanical recycling is either associated with down-cycling or there are no recycling streams at all.

The F385 CIRC-CASE IPHONE®, a phone cover made from discarded ski boots, which was developed in co-operation of IWK with FREITAG®, is one of the projects addressing this issue and demonstrates that a closed loop circle for old TPU ski boots is feasible.

In the first step, the ski boots are collected and sorted at ARGO in Davos (a workshop for people with disabilities). The boots are disassembled, and all metal parts are separated. Afterwards, the polymer type is detected with the help of FTIR, and the parts are sorted by colour and shredded in a mill. The obtained flakes are then processed in the compounder at the IWK to remove possible residual contamination and to receive homogenous pellets.

The iPhone covers, which are then produced via injection moulding, are made of 100% recycled TPU and can be recycled again at their end-of-life within Freitag’s established Take-Back system.

In addition to creating a closed material loop, the project also shows the potential of local production since the whole value creation takes place within 150km around Zurich in Switzerland.

One of the major challenges in mechanical recycling is odour reduction, especially for polyolefin materials like PE and PP. In a project with Tide Ocean SA and the IWK, possible process optimisations and material modifications were evaluated. The goal was for the ocean-bound rPE and rPP material from Tide Ocean SA to fulfil the high requirements of the automotive industry standard VDA270.

As part of a defined set of experiments, different screw configurations, degassing options, activation concepts, and the application of an entertainer for the removal of volatile organic compounds (VOC; source of odour development) were tested. As a result, material and process optimisation concepts were developed to meet the requirements of VDA270.

In addition to this project, Tide Ocean SA and IWK developed an innovative upcycling process and quality standards for collecting, sorting, compounding, and injection moulding that allows the production of high-quality products from ocean-bound rPET. The granules can replace virgin plastics without loss of quality in a variety of production processes, including 3D printing, textile fabrication, and injection moulding.

An example of successful co-operation is a watch from Maurice Lacroix, in which the bezel, housing, crown, end, and closure parts are made from recycled ocean-bound rPET material.

Organic recycling – What is the impact of bioplastics?

The use of bioplastics to replace conventional fossil-based materials is by now state-of-the-art in the plastics industry. However, bioplastics are also associated with various controversies, including competition with food and unclear disposal/recycling routes. The FluidSolids AG is tackling this by offering materials based on secondary resources that are 100% home-compostable. Together with the IWK, the compounding process was optimised, and scale-up was achieved. Disposable cutlery made of FluidSolids material can be found in Swiss supermarkets today.

Paper recycling – Paper as a replacement for plastics?

Especially in the field of packaging, regulations and consumers are pushing for a reduction in the use of plastics and a change to alternative materials. In that context, paper and paper-based materials are gaining increasing importance and potential for the polymer industry. However, replacing plastics with paper is not trivial since the material and processing properties are completely different.

Founded by the ‘Neue Regionalpolitik’ (NRP) of the canton Fribourg, the IWK, together with the iRAP (Haute école d’ingénierie et d’architecture Fribourg) and 11 companies investigated the feasibility of the potential of paper in plastic processes. Existing paper-based materials were analysed, and their processability was tested successfully (injection moulding, extrusion, thermoforming).

Challenges and needed adaptions regarding tools, material composition, and process parameters were identified and translated into the next steps, which are currently being worked on in follow-up projects. The project showed that while paper-based materials will certainly not replace plastics in all (packaging) applications, they are a useful addition to the existing material and property portfolio.

Chemical recycling – the future?

Chemical recycling is one of the big hopes for a circular plastics industry since it offers the possibility of recycling mixed plastic waste and getting recycled materials with virgin properties, something that is (currently) not possible with mechanical recycling.

There is a variety of chemical recycling processes available, but none of them are on a commercial scale yet. This makes a final comparison between chemical and mechanical recycling regarding their environmental impact nearly impossible. However, it must be expected that chemical recycling will most likely have a higher energy demand and should, therefore, only be installed as a complementary recycling route to mechanical recycling, for example, in textile recycling, where mechanical recycling is difficult due to the often-high cotton content.

Summarising: the plastics industry has several possible pathways toward circularity. No ‘circle’ should be favoured above another one without considering the boundary conditions of the individual application. All the more, the synergies between the existing as well as emerging recycling technologies can act as a positive driver for sustainability.

Please note, this article will also appear in the 18th edition of our quarterly publication.