Researchers of the Technical University of Munich and the University of Applied Sciences highlight the potential of biosorption as a promising eco-friendly alternative to conventional REE recovery methods.

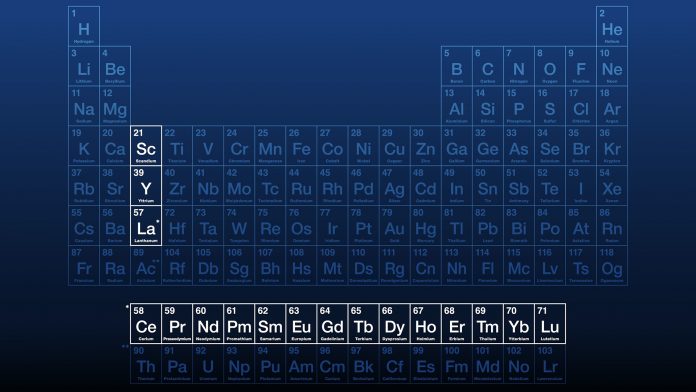

The expression rare earth elements (REEs) refers to a group of 17 elements, which include scandium, yttrium, lanthanum and 14 additional elements of the lanthanide series. In this context, the term ‘rare’ is misleading as it does not relate to geological scarcity but results from the occurrence of REEs as a mixture of elements in mineral deposits in very low concentrations.

For many applications in high-tech sectors, such as computers, electric vehicles, chemical catalysts, and renewable energy, REEs are vital. They have very similar chemical properties making the purification of REEs on an industrial scale difficult and energy-intensive. Nevertheless, due to their unique magnetic, luminescent, and electrical characteristics, they are of significant interest to today’s economy.

The current global rare earth landscape

Despite their broad distribution, only a few deposits have adequately high concentrations to support commercially viable production. As a consequence of their low concentration in initial raw materials and the subsequent complex and energy-intensive purification, REE production is unprofitable in a stand-alone mining operation. Hence, REEs are typically produced as a co-product or by-product of other materials. For example, a significant portion of the world’s REEs is derived from by-products of iron mining in the Bayan Obo mine located in China.

In the past, China was the most important exporter of REEs for many years. The price of REEs increased dramatically after China placed export limits on the minerals in 2010, thereby making it apparent that these elements are vital for numerous key industries. As a consequence, many countries have been working to establish their own REE production in an attempt to gain economic and political independence. Today, China controls 60 to 70% of the global annual REE production, which was estimated at 300,000 metric tonnes in 2022.

REE recovery from wastewater streams

The release of REEs into the environment rose rapidly with considerable increases in industrial output. According to recent research, the accumulation of REEs in the environment may have a deleterious influence on a variety of ecosystems. Additionally, there are indications that long-term exposure to elevated REE levels may be harmful to human health.

Hence, there is an incentive to remove REEs from industrial wastewater streams. Unfortunately, common industrial wastewater treatment systems are designed for the removal of toxic heavy metals, such as lead, mercury, or cadmium, and are not specifically intended to remove REEs from wastewater. As a result, their efficiency in recovering REEs usually is relatively poor.

Removing REEs through biosorption

A recent study, published by researchers of the Technical University of Munich (TUM) and the University of Applied Sciences in Kaiserslautern in Frontiers in Bioengineering and Biotechnology in February 2023, described various cyanobacteria that were able to passively adsorb REEs from aqueous solutions. This process, called biosorption, is widely regarded as a promising eco-friendly alternative to conventional REE recovery methods and has gained increasing attention in the scientific community over the past years. It is especially considered a viable option for metal removal from highly diluted aqueous solutions. Typically, most studies have focused on the removal of environmentally toxic heavy metals, such as mercury, lead, or arsenic. Yet, the recovery of other elements, including precious metals such as gold, platinum, and palladium has been tested.

Biological materials comprise numerous different constituents that can facilitate the attachment of specific molecules to their surface. Depending on the chemical composition of the biomaterial, the adsorption properties vary in terms of total adsorption capacity and binding specificity for particular molecules. In that context, cyanobacterial biomass has been demonstrated to be well suited for metal adsorption, as it often contains high proportions of negatively charged components, such as uronic acids or sulphated polysaccharides. These negatively charged functional units exhibit an electrostatic attraction towards positively charged ions, in particular metal ions, which enhances the interaction of the metal with the biomass. Typically, the adsorption results in metal accumulation at the biomass surface.

The study on metal biosorption by cyanobacteria demonstrated that REEs and other metals, such as lead or aluminium, compete for the same active binding sites accessible at the surface. During biosorption, these metal cations replace other cations, present in the biomass, that apparently exhibit a weaker attraction in an ion-exchange process. As a result, those metals are released into the water and have been identified as sodium, potassium, magnesium, and calcium.

A biosorption-based process typically begins with incubating the biomass used as a biosorbent in aqueous solutions containing various metal elements. The biomass can be stirred in a tank or immobilised and placed into a column. REE ions are extracted from the solution and bind to the surface of the biomass depending on the adsorption characteristics of the biomass and the environmental factors during the process, such as pH value, metal concentration, or metal ion composition. Interestingly, it was demonstrated that cyanobacterial biomass, at low metal concentrations, exhibits a higher affinity for REEs than for other metal ions.

Following the adsorption step, the metal-enriched biomass can be retrieved from the aqueous solutions using methods, such as sedimentation, filtration, or centrifugation. This process step is not required in systems based on immobilised wood. Finally, REE recovery can be carried out using destructive processes, such as pyrolysis or burning, which result in REE-rich ashes, or through selective elution of adsorbed metal ions.

From an economic standpoint, the last-mentioned process is preferable as this biomass can be reused following a regeneration step. Adsorbed REE ions can be released from biomass by, for example, adjusting the pH value or adding metal-complexing compounds such as citric acid or ethylenediaminetetraacetic acid. One significant disadvantage of biological sorption materials in this scenario is their poor long-term stability. After a few cycles, the adsorption properties of biological materials gradually degrade. This is a subject that is currently being worked on in order to increase industrial applicability.

Implementing biosorption-based systems in the future

Currently, the implementation of a REE recovery process based on cyanobacterial biomass is being tested in cooperation with operating mining and metallurgical companies. In this context, a scale-up of the developed system has to be achieved and the application of wastewater streams with varying metal compositions to the biomass has to be tested. Results of this running endeavour are expected within the next five years.

Compared to conventional metal recovery processes, biosorption-based systems still have high operational costs. However, biosorption allows metal recovery from highly diluted solutions and can be adjusted for the removal of metals that cannot be recycled effectively with commonly used methods. With rising demands for specific elements that are required for high-tech applications, such as lithium, gallium, and especially REEs, their market value is expected to rise significantly in the near future.

Currently, REEs are considered a critical resource with a high supply risk and might become a limiting factor for future technological progress. Thus, it is advisable to explore new sources, production routes, or recovery strategies for those raw materials in order to maintain political and economic independence. In that context, biosorption-based REE recovery has great potential for future applications in wastewater treatment and metal recovery from aqueous industrial and mining effluents.