Electric vehicles (EVs) are essential for reducing carbon emissions and promoting sustainability in the transportation sector.

However, while they contribute to environmental goals, the materials used in their components, including electric motors, often come under scrutiny.

Sustainability is a complex concept influenced by various factors, but certain technologies and practices can significantly affect the overall environmental impact of electric motors.

According to a recent report by IDTechEx, the demand for electric motors will skyrocket, reaching over 160 million units per year by 2035.

This growth highlights the importance of designing motors that prioritise sustainability, especially given their role in an EV’s performance and efficiency.

Material choice and environmental impact

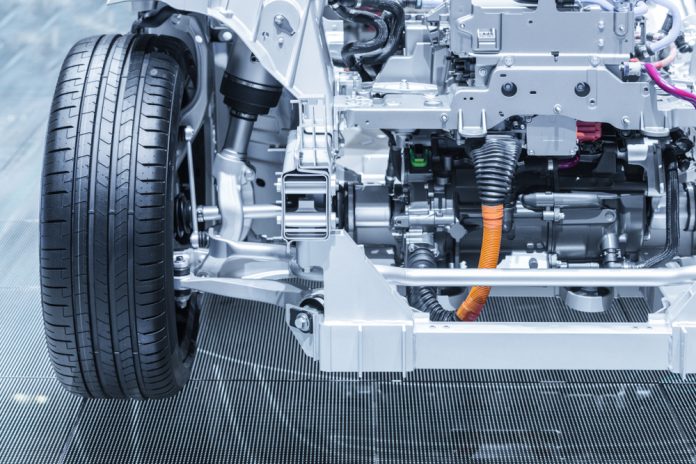

One of the primary considerations in the design of electric motors is the choice of materials. Most electric motors in EVs use steel laminates and copper windings in the stator.

However, the key distinction lies in the materials used in the rotor. Rare earth permanent magnet motors dominate the market, accounting for 85% of electric car motors in 2023, according to IDTechEx.

While rare earth materials are critical for motor efficiency, they pose significant environmental challenges.

Per kilogram, rare earths have the highest environmental impact compared to other motor materials like steel, aluminium, and copper.

Some methods of their extraction and processing can contribute to issues like ozone depletion, global warming, and acidification.

Though rare earths comprise only a small portion of the motor, their overall environmental footprint per kilowatt of power is higher than that of magnet-free motors.

However, it’s not all straightforward. Magnet-free motors, while less reliant on rare earths, often require more copper and may involve energy-intensive manufacturing processes. This creates a trade-off between material choice and manufacturing impact when considering sustainability.

Improving electric motor efficiency and power density

Increasing the efficiency of electric motors is crucial for enhancing the sustainability of EVs. A more efficient motor wastes less energy, reducing the electricity required to power the vehicle.

This, in turn, lowers CO2 emissions, especially in regions where electricity generation relies on fossil fuels. Additionally, efficient motors allow for smaller batteries, reducing the overall material usage and environmental impact of the EV.

Power density is another key factor. Motors with higher power density can achieve the same performance with fewer materials.

For example, axial flux motors are capable of delivering 190kW of power with less than 1.2 kg of magnets, a stark contrast to traditional radial flux motors that require around 10 grams of magnets per kilowatt.

By minimising material usage, high-power density designs can significantly contribute to more sustainable electric motors.

The push for more motors in EVs

The trend toward multi-motor configurations in EVs, such as dual, tri, or quad motors, has increased the average number of motors per vehicle by 13% since 2015.

While this improves vehicle performance, it also raises concerns about material consumption and the associated environmental impact. More motors mean more materials are needed for the motor itself and the related electronics and thermal management systems.

However, the demand for more motors isn’t solely driven by necessity. Higher-spec vehicles with multiple motors offer better performance, which is a desirable feature for many consumers.

While this may reduce the sustainability of individual vehicles, it could encourage more widespread adoption of EVs, which benefits the environment in the long run.

Electric motors: Balancing sustainability with performance

While sustainability is a critical goal for automakers, factors like performance, efficiency, and cost often take precedence when designing electric motors.

Although the focus has primarily been on improving battery technology, electric motor sustainability will likely gain more attention as the industry progresses.

Currently, European regulations, such as the battery passport, focus on reporting the CO2 footprint of EV batteries.

However, as the industry evolves, electric motors may also become a key area for sustainability improvements, potentially reshaping the future of EV design.