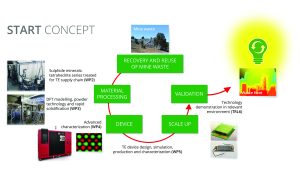

The START project aims to produce thermoelectric devices for waste heat recovery applications from secondary mineral resources (mining waste).

The START project is co-funded by the European Union (EU), Grant Agreement No 101058632, via its Horizon Europe programme, under the topic ‘Building innovative value chains from raw materials to sustainable products’ (HORIZON-CL4-2021-RESILIENCE-01-07).

It is a breakthrough project that aims to use secondary resources from mining waste and tailings to develop sustainable tellurium-free thermoelectric (TE) devices.

START approach and concept: Recovering heat from mining waste

The ultimate goal is to build an innovation ecosystem in the EU related to the production of TE devices with the highest economic efficiency suitable for use in waste heat recovery systems.

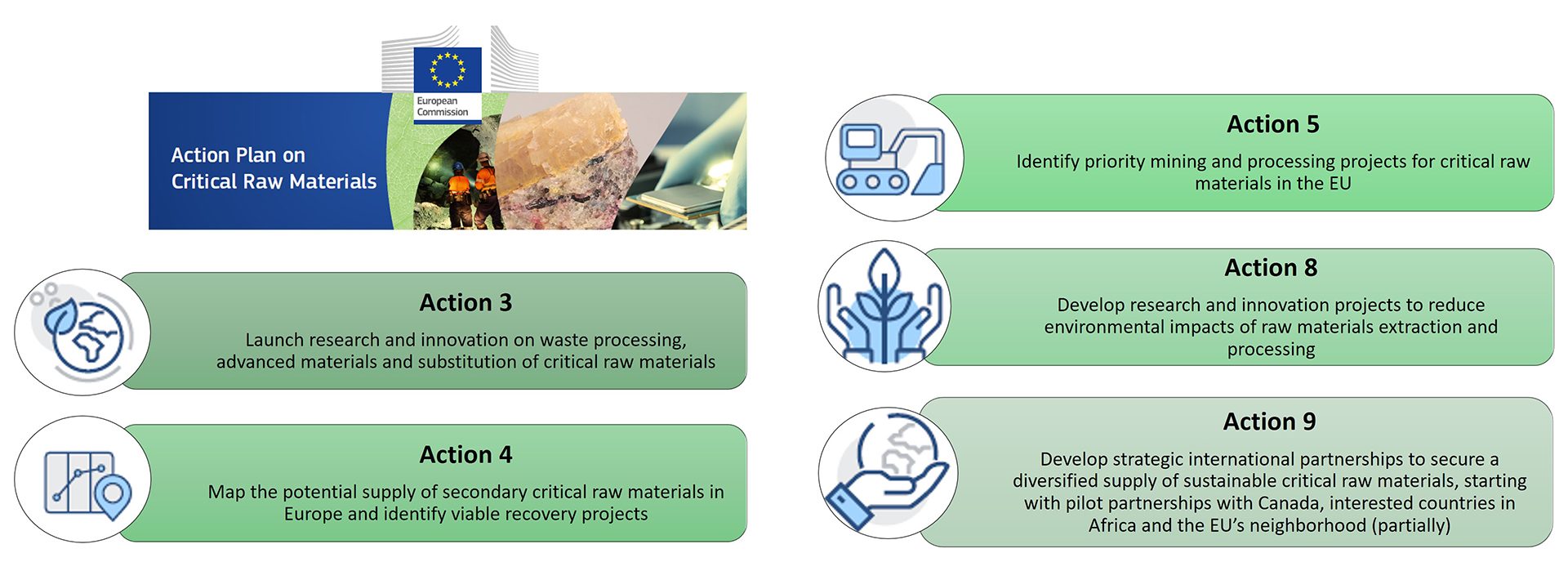

This represents an opportunity to efficiently use the EU’s discarded secondary resources, reduce its waste and dependency on third countries, and offer a competitive solution for the sustainable development of renewable energy ecosystems using TE systems, in line with the strategies outlined in the European Green Deal and the EU Action Plans on Critical Raw Materials and Circular Economy.

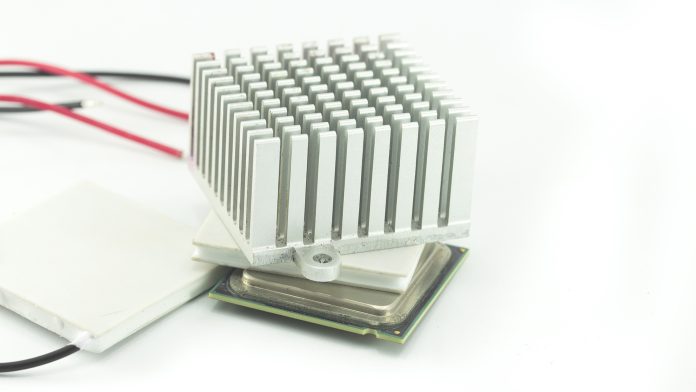

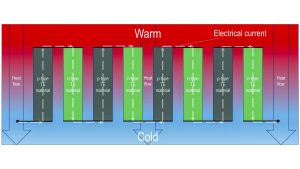

A TE device is a solid-state energy converter made from several TE junctions electrically connected in series that consist of n- and p-type TE semiconductor materials (Fig. 1). It converts thermal energy into electrical energy. It possesses unique attributes: No moving parts, no maintenance, quiet operation, and absence of production of environmentally deleterious mining waste.

Currently, most commercial TE devices use bismuth telluride (BiTe) or lead telluride (PbTe) as TE materials, which depend on the availability and price of tellurium. Considering, simultaneously, that China is responsible for around 60% of the world’s tellurium production and the restrictive export policies it has recently adopted about certain raw materials, this dependence on tellurium-based materials becomes a huge disadvantage that hinders the large-scale implementation of TE technology in Europe.

To overcome this issue, START is proposing a solution based on the production of p-type materials that incorporate abundant sulphide minerals not currently in use, the tetrahedrite-tennantite mineral series, a copper antimony sulfosalt mineral, with generic formula (Cu, Fe)12(Sb, As)4S13, which does not contain tellurium in its composition. These minerals are being collected in the respective European countries of the Geological Survey institutions included in

the consortium.

The general concept of the START project is based on a ‘waste material-waste heat to power’ methodology (Fig. 2), which is the genesis of a completely new value chain linking secure European mineral resources and energy production. At the same time, it also contributes to the advancement of scientific knowledge and technological innovation in the field of thermoelectrics, as well as promoting a decarbonised society.

START outcomes

START will have many outcomes. By creating an innovative, flexible, scalable, adaptable mineral-derived value chain for TE devices based on raw materials that are readily available in Europe, START will create a new rapid-growth commercial ecosystem that will attract new stakeholders exploiting market opportunities for replication and market development.

In fact, this will be a new market opportunity for European mineral resources, converting discarded waste secondary sulphide materials available in Europe into useful and valuable mineral resources, boosting EU competitiveness on raw materials through the recycling of such mining waste, fostering the transition to a greener society and economy through eco-innovation, and promoting energy security.

START impact

START strengthens and expands the European raw materials supply sector by replacing a key component of thermoelectric (TE) devices with new materials sourced within the EU. This will substantially contribute to the main expected impact of Cluster 4 (‘Industrial leadership and increased autonomy in key strategic value chains’) of the Horizon Europe Programme. It is then expected to impact several areas significantly, as explained below.

For the environment, START plans to reprocess sulphide-containing mining residues, thereby reducing the environmental impact of mining activities by remediating potential acid mine drainage while preventing the loss of valuable resources currently ending up in mine tailings.

START will address the sustainable supply of raw materials, securing a reliable supply of raw materials for green technologies and, more specifically, for TE applications, as it aims to replace the current TE materials (BiTe and PbTe) and produce tellurium-free TE devices based on tetrahedrite. This mineral in START is being sourced from European mining sites.

Regarding materials and technology innovation, START is using scalable and cost-effective methods for producing high-quality p-type tetrahedrite powder materials that will be assembled into the TE devices. The production of tetrahedrite powders by High-Energy Ball Milling has already been scaled up to pre-pilot capacity. Innovations in assembling TE modules for demonstration are also being adopted.

The goal of promoting the development of a sustainable society is pursued by several dissemination and communication activities about the project aims and topics to inform about the benefits and potential of the TE technology and the importance of ensuring secure, sustainable and competitive supply chains for green technologies in Europe. The project has also started a benchmark analysis of life cycle assessment (LCA) and life cycle costing (LCC) studies to evaluate the environmental and economic impacts of its TE devices compared to conventional ones.

Thus, the START project also contributes to the UN Sustainable Development Goals 7 (affordable and clean energy), 9 (industry, innovation and infrastructure) and 11 (sustainable cities and communities) and to the implementation of the actions of the EU Action Plan on Critical Raw Materials outlined in Fig. 3.

START main achievements during the first 15 months

In accordance with the specific objectives planned, START already obtained some important results.

Concerning the objective of developing a resilient and sustainable raw materials supply chain for the TE technology, first of all, donor sites containing mineralogically suitable sulphide minerals for producing the p-type semiconductor thermoelement were identified in various historical European mines, based on: The volume of sulphides; the presence and content of tetrahedrite; and accessibility and logistical issues. Sampling protocol methodologies have been established that follow a scientifically sound approach to sample collection and subsequent treatment.

Based on this, several hundred kilogrammes of discarded mining waste sulphides were collected. Tetrahedrite-rich concentrates from these minerals were successfully processed via High Energy Ball Milling (HEBM) in a pre-pilot scale (300g batches) to produce kilogramme-scale batches of mineral-derived tetrahedrite p-type powder materials incorporating different amounts of synthetic material to adjust the composition. Spark Plasma Sintering subsequently achieves the production of mineral-derived tetrahedrite p-type thermoelements. Work is progressing to optimise the composition, performance, and maximum amount of mineral concentrate that can be added to the initial mixture simultaneously. At the same time, a compatible n-type TE material was identified.

Based on simulated performances, two applications for the TE devices have been defined: Combined heat and power (CHP) and low-grade waste heat from heavy industry. Work is underway to assemble the first TE device of the START project.

To define the commercial ecosystem and business environment, a comprehensive analysis towards benchmarking the life cycle assessment (LCA) and life cycle costing (LCC) studies to measure the environmental and economic performance of the TE devices has started. The first component of the prospective exercise, i.e., focus groups, was initiated to assess the market perspective and social acceptance. A first-round Delphi Survey was prepared.

Dissemination/communication activities were carried out, including the publication of a biannual project newsletter entitled ‘RECOVER-REFORM-REUSE for a Sustainable Future’ (available on START’s website), the organisation of three free webinars on project activities, whose videos are accessible on START’s YouTube channel (more are being organised in 2024), and the multilingual comic storyboard ‘Starty explains START’, where Starty, a robot character, addresses and explains the project topics in an easily understandable way.

START consortium

The START project is co-ordinated by LNEG, a Portuguese public research and development institution. It brings together a total of 15 partners (Fig. 4) from ten EU countries and one associated country, including: Six research organisations with strong knowledge of geology, materials science and renewable energies; seven SMEs that cover the entire supply chain from production to exploitation and ecological footprint assessment; and two non-profit international associations with a wide network of partners and stakeholders.

Co-Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.

Please note, this article will also appear in the 18th edition of our quarterly publication.