Dr Hadi Moztarzadeh, Head of Technology Trends at the Advanced Propulsion Centre (APC UK), reviews current industry innovation to address a lithium shortage and details the impact the economic climate will have on automotive production and demand globally, in Europe and the UK.

It is a critical time for the UK automotive industry and, as we drive into 2023, the industry finds itself at a pivotal point. Governments and policymakers around the world have set clear emissions reduction targets. The UK has set the pace for the decarbonisation of transport, leading the way globally to limit temperature rises to 1.5°C, on the journey towards net-zero emissions globally by 2050. However, the Energy Monitor states that emissions must now fall twice as fast as the rate at which they have increased since 1990 if global warming is to stay below 2°C. A challenging task ahead for all nations.

Ambitious targets for the automotive industry

By 2025, light duty vehicles (LDVs), including both passenger cars and commercial vans, must meet an EU-wide fleet average CO2 emissions reduction of 15% according to the 2021 baseline. From 2030, sales of new petrol and diesel cars will come to an end.

We are only three years away from 2025, and just seven years away from a ban on the sale of new petrol or diesel cars in 2030. Both are significant milestones for the automotive ecosystem which creates an enormous opportunity for the entire UK PLC to prosper with innovation happening at pace as original equipment manufacturers (OEMs), their partners, and supply chain look to meet these targets with technologically robust electric powertrains. This positions the UK well to meet the challenges posed by net zero and offers a huge opportunity for the UK to generate jobs, inward investment, and a world-class automotive industry.

Accelerating the UK automotive sector

The Advanced Propulsion Centre (APC) is uniquely placed to keep account of global influences, supplier concerns, OEM capability, and future research and development (R&D). APC’s unique role across the automotive ecosystem and its relationship with industry, academia, and intermediary funding and policy bodies ensure that, collaboratively, we drive strategic and commercial outcomes for the benefit of the UK automotive sector and the wider economy. Our bridging role, between industry, research and innovation, and policymaking means we are best positioned to support the whole automotive sector, up and down the ecosystem, to shape the future of transport and take a science superpower to an industrial superpower.

With a dedicated Technology Trends team monitoring and analysing the industry, a picture is emerging of a sector that is well-placed to handle the transition to net-zero technologies for the automotive industry, if the right support is put in place now to establish and secure localised supply chains, funding, and skills.

This is the biggest transition for the automotive sector we have seen since the introduction of the internal combustion engine (ICE), and this brings with it significant opportunities and challenges. Value chains for all elements of powertrain production are impacted, workforces need to be re/up-skilled and retained, investment needs to be made, and supply chains need to be established and secured – all against a backdrop of economic uncertainty.

Critical minerals shortages

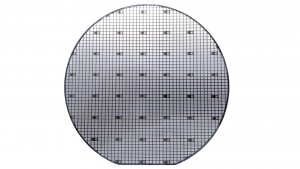

One of the biggest factors facing automotive OEMs is the issue of access to critical minerals, specifically lithium, as a shortage could impact the number of batteries manufactured. A recent report released by the APC pointed to battery electric vehicle (BEV) production in both the UK and Europe being revised marginally downwards due to project and production delays, impacted by the current economic uncertainty and supply chain issues.

However, the APC’s Technology Trends team believes that the potential lithium deficit we expect to see in 2030 could be reduced by as much as 40%, based on future modelling scenarios that have been conducted to assess the impact of different solutions. These could include manufacturing BEVs that require alternative battery chemistries, such as substituting lithium with sodium-ion in smaller vehicles and shifting some BEV production to fuel cell electric vehicles (FCEVs); plug-in hybrid electric vehicles (PHEVs); and range extender vehicles.

The potential impact a lithium shortage could have includes an energy density impact of different chemicals; an impact on battery size and range; supply chain issues; and sourcing outside of China.

Rapid development in battery technologies

So, what is next for UK-based OEMs? What we do know is that scientific innovation in the automotive sector is happening at pace. There are eight emerging battery technologies we can point to that have been identified as the most promising in the automotive sector, but these are currently all at various levels of commercial opportunity and manufacturing readiness. The technologies are:

- Silicon-dominant anodes;

- Manganese-rich cathodes;

- Industry-scale battery materials recycling;

- Solid-state electrolytes;

- Lithium metal anode;

- Dry electrode manufacturing;

- Lithium techniques; and

- Sodium ion.

The UK is well-placed to anchor R&D for these technologies and, with the automotive industry set to account for 80% of battery demand by 2030, the need for investment in R&D now is critical. APC insights highlight that the UK could focus on levering its strategic advantage in sodium ion and silicon dominant anodes, but also raises the issue that there are no cathode or anode active material producers manufacturing in the UK with heavy reliance on imports. To ensure the UK’s future battery ecosystem is robust, we need to attract leading material suppliers.

With battery demand of over 2,900 GWh by 2030 and a looming lithium shortage, opportunities to reduce the reliance have been highlighted by the APC’s Technology Trends team who, in their insight reports, point to exploring potential pathways to ensure lithium demand remains sustainable including:

- Manufacturing BEVs with smaller batteries;

- Substituting lithium with sodium-ion in smaller vehicles; and

- Shifting some BEV production to FCEVs, PHEVs, and range extender vehicles.

Reducing battery pack sizes on vehicles is an important consideration. The APC’s 2022 insights and quarterly demand reports have identified a range of scenarios to achieve this. For example, an opportunity highlighted by APC’s quarterly demand report is the switching of onboard power electronics from silicon (Si) to a chemical compound called silicon carbide (SiC) which would offer efficiency gains of 10%. Together with an 800V+ electrical architecture, this could save 3-5% in battery mass. Smaller battery packs have a reduced need for lithium (and/or other critical minerals), and the added benefit of reducing overall vehicle cost. Moving forward, the UK automotive sector needs to secure end-to-end supply chains for these critical materials.

Economic impact

The current economic situation could act as a pull to prioritise some of the points we have made above. Consumers are feeling the impact of their finances being squeezed and could be less likely to purchase new cars or, if they do, the expectation is that they would look to buy smaller vehicles. The outcome of this would result in smaller batteries, which will subsequently mean less impact on lithium resources, and lower overall vehicle cost. For OEMs, this means looking to focus manufacturing on smaller batteries, which will of course mean lower costs for OEMs.

Demand for electric vehicles here in the UK and globally has an uncertain outlook, owing to the global economic climate. Forecasts for vehicle production over the next eight years are undetermined and we expect to see a reduction of one million vehicles manufactured in Europe in 2030, compared to the figure forecast last quarter. There is no magic wand.

We must work hard now to apply innovations to real-world scenarios and to build and invest in the UK supply chain to support the electric vehicle manufacturing industry. However, while economic uncertainty is sure to have an impact on forecasts, what we do know is the transition must and will happen. We believe forecasting beyond the 2030 mark is unchanged.

The UK is well-placed to weather the challenges of the next few years. With the right funding support, workforce upskilling, and commercialisation, together with the technological readiness of the wealth of R&D and innovation that is out there, the transition will happen. One of the support mechanisms in place is the APC’s Automotive Transformation Fund (ATF), which was launched in 2020 with up to £1bn of funding allocated to support the UK automotive R&D and manufacturing sector. APC aims to build on the UK’s global leadership position in scientific research, automotive engineering, and net zero political ambition by enabling de-risking of new products and process development, supporting both the domestic and export markets. With over £1bn invested in APC programmes to date, significant progress is being made, growing the UK’s capabilities, safeguarding jobs, and reducing emissions.

Dr Hadi Moztarzadeh

Head of Technology Trends

Advanced Propulsion Centre

https://www.apcuk.co.uk/

https://www.linkedin.com/company/advanced-propulsion-centre-uk/

https://twitter.com/theapcuk

Please note, this article will also appear in the thirteenth edition of our quarterly publication.