Finding solutions to tackle the issue of plastic packaging waste is urgent. VTT has mapped out three paths that brands and packaging manufacturers can take to maximise sustainability and minimise the carbon footprint of packaging.

Plastics have many benefits as packaging materials: they are designed to be strong and long-lived, while enabling light-weight and highly protective solutions. However, when these materials enter our ecosystems, forests, rivers and seas, they cause severe harm to the environment. In addition, plastics are mostly produced from fossil feedstocks, contributing to carbon emissions and climate change. Currently, the majority of plastic packaging are single-use and are not part of the more sustainable, circular economy.

The demand for innovative solutions is strong. Both eco-conscious consumers, policymakers and industry leaders are urgently pushing to create more sustainable packaging. The EU strategy focuses on achieving 100% recyclability, reusability, or compostability of packaging materials by 2030. Global consumer-brand heavyweights like Evian, L’Oréal, Mars, The Coca-Cola Company, Unilever, and Walmart have announced their aim to achieve this goal in their packaging five years earlier, by 2025 or earlier. Therefore, it comes at no surprise that the market for green packaging is expected to grow to USD 297 billion by 2024.

As a visionary research and development partner committed to sustainable development, VTT can help companies turn the plastics challenge into a competitive advantage through novel scientific and technological solutions.

According to our vision, the adverse lifecycle effects of plastic packaging can be cut in half by 2030. Our goals are clear: we must stop plastic packaging ending up in nature by improving reuse and recycling methods. Additionally, reducing the carbon footprint of packaging is essential. These goals can be achieved through a shift from a linear to a circular economy of plastics. This shift requires rethinking the materials and process: an eco-design to ensure circularity in every step.

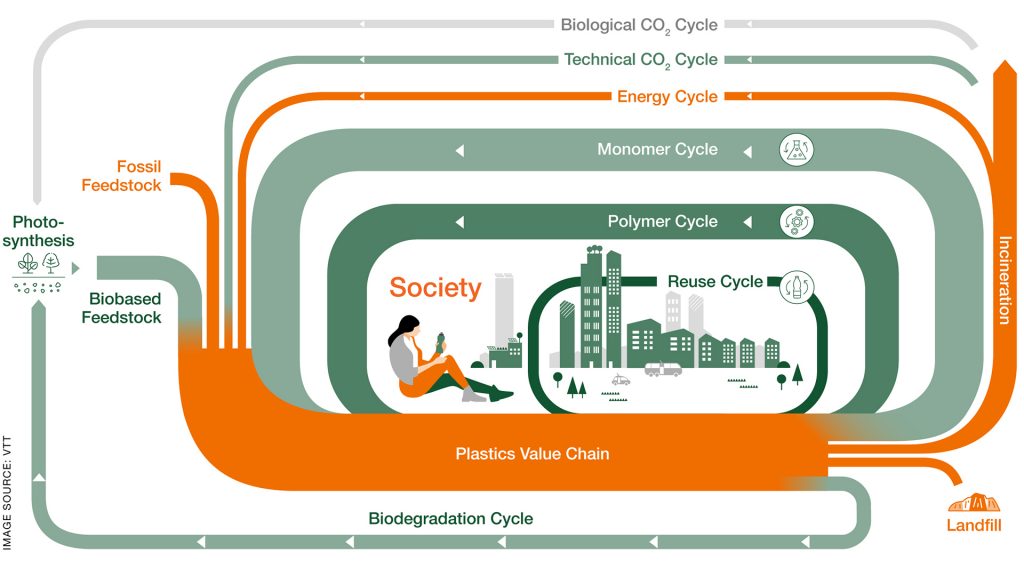

To realise its circular economy vision, VTT is researching and developing various solutions that would allow for a circular economy to be implemented as shown in the infographic above. The orange paths display the current situation of the plastics economy. The green paths show the ways in which material circulation can be achieved.

- Reuse cycle: the circulation of products and individual goods.

- Polymer cycle: macromolecular level.

- Monomer cycle: component level.

- Biological cycle: biodegradation to soil.

- Biological carbon cycle: biodegradation to carbon dioxide and methane.

- Technical carbon cycle: capture and utilisation of carbon dioxide.

- Energy cycle: energy recovery.

Three routes towards the circular economy of plastic packaging

How can brands, packaging designers and manufacturers enable the shift towards the circular economy for plastics? We have outlined the three most feasible routes for more sustainable packaging.

Shift to biobased materials made from sustainable feedstocks

Transitioning from fossil-based plastics to alternative materials made from renewable feedstocks can significantly reduce the carbon footprint of packaging. Bioplastics can offer similar or improved properties compared to traditional plastics without the use fossil raw materials.

The challenge here is to develop and secure a sustainably sourced virgin feedstock from biomass. We at VTT have developed solutions using food waste streams, such as sugar beetroot or citrus peel, or renewable forest biomass. It is important to ensure that biobased alternatives are high-performing and scalable up to commercial production.

They should support circularity i.e. they are easy to reuse, recycle, biodegrade, or preferably all of these. These features do not come as a given; they require long-term commitment to research and development.

VTT has already created several biobased packaging solutions which are at different levels of development:

- Our award-winning cellulose-based packaging material is both compostable and lightweight and can extend the shelf life of dry foods, while reducing waste and helping resolve the global microplastics problem.

- VTT helped Woodly create a low-carbon bioplastic based on wood fibre. The solution is already in commercial use as the packaging material of Järvikylä herbs and salads.

- VTT’s new foam-formed, cellulose-based material is an eco-friendly alternative packaging and cushioning material to expanded polystyrene. Made of 100% renewable wood pulp it can be recycled like cardboard or composted like paper.

Design easy-to-recycle packaging

Currently up to 95% of the value of plastic packaging materials is lost from the economy due to the material being only used once. To achieve the circular economy of plastic packaging, we need to ensure that packaging designs, whether they use traditional oil-based plastics, biobased solutions or both, enable effective recycling.

This means producing either highly reusable or repairable packaging, or creating designs with easily recyclable materials.

To ensure reusability, packaging materials must be durable, robust and free of harmful additives. In some cases, such as plastic bottles, technologies are already available to chemically repair the polymer to multiply its use-cycles.

The second path is simplifying packaging designs and materials to enable easy recycling. High-performance food packaging materials, for instance, are usually composed of complex layers of different polymeric materials, which makes recycling complex. By reducing this complexity or designing it in a way that allows for different materials to be easily separated, we can greatly enhance recycling capabilities.

VTT has a wide understanding of every phase of the circular economy of plastics, from new, sustainable materials, to mechanical and chemical recycling technologies, as well as degradation and biotechnical recycling. Thus, we can help companies design packaging solutions that take circularity into consideration every step of the way.

We can help companies assess of the lifecycle effects of different materials and design scalable packaging solutions that facilitate a high degree of circularity. These services can also be combined with new materials research and development.

Enhance biodegradability

Degradation and composting is a sustainable route out of circularity without spoiling the environment. Currently, most plastics biodegrade very slowly. Consequently, science and technological development has concentrated on developing biodegradable plastics and accelerating biodegradation of plastics with biotechnical recycling solutions.

VTT can help companies design new packaging materials with enhanced biodegradability, whether they are of biobased origin or made from fossil raw materials. In addition, we work on creating biotechnical recycling solutions, such as the identification and alteration of plastic-degrading microbes and enzymes. For example, VTT’s PlastBug initiative seeks to develop microbes that degrade selected plastic waste into valuable products like fuels and chemicals.

Finding the right sustainable packaging solutions is not an easy task; it requires considerable investments and long-term commitment to research and development. VTT’s expertise will not only help companies research and develop but also scale up and commercialise new circular solutions. As the demand for sustainable packaging grows, we believe there are great benefits to gain for early adopters of the circular economy of plastics.

Read more about the topic from VTT’s publication: A Circular Economy of Plastics. The development of the roadmap involved VTT’s leading experts from the following fields: polymer design, plastic production, product development, recycling technologies, circular economy and bioeconomy.