The newly released report by The Boyd Company, Inc., has listed the top 30 US cities positioned to attract investment in the electric vehicle supply equipment industry.

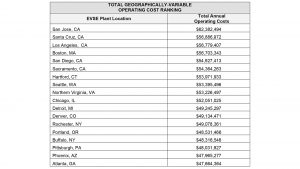

The Boyd report compares annual operating costs for a typical electric vehicle supply equipment (EVSE) manufacturing plant in each of the surveyed cities. Costs range from a high of $62.4m in San Jose, California, to a low of $43.7m in Chattanooga, Tennessee, for a 500-worker plant.

About the electric vehicle supply equipment industry

The EVSE market is projected to grow from $7bn in 2023 to $100bn by 2040. This growth is led by charge point operators that manufacture, operate, and service EV charging stations.

Recent PwC analysis has found that the EV charging market will need to grow almost tenfold to meet the charging needs of an estimated 27 million electric vehicles on the road by 2030.

The number of US charge points is predicted to increase from around 4 million in 2023 to approximately 35 million in 2030.

EVSE growth is boosted through Federal Government incentives

The Bipartisan Infrastructure Law has earmarked $7.5bn for EV charging and developing a national electric vehicle charging network along designated Alternative Fuel Corridors.

The Biden Administration has also set up the NEVI programme to help states build a coast-to-coast network of qualifying fast chargers. This provides $5bn in funding over five years.

A $2.5bn Discretionary Grant Programme has also been established. This aims to increase EV charging access in rural and underserved communities.

The Inflation Reduction Act’s $3bn dedicated to supporting access to EV charging in economically disadvantaged communities will serve alongside this.

NEVI aims to facilitate domestic battery production

Many EV components are sourced outside the US, with manufacturers having to import them through an expensive and geopolitically risky global supply chain.

US battery manufacturers alone are estimated to spend more than $150bn overseas on key inputs by 2030.

NEVI funding is designed to mitigate these EV supply chain risks. The programme will work alongside the Federal Highway Administration’s Build America, Buy America Act, which encourages the reshoring of manufacturing investment from China and elsewhere.

NEVI includes two phases, which first required manufacturers to conduct final assembly and all manufacturing processes for any iron or steel charger enclosures or housing in the US from 23 March 2023. Second, by July 2024, 55% of the cost components used in charging equipment must be sourced domestically.

Because of this, the electric vehicle supply equipment industry is currently one of the top sectors for economic development in the US.

Top cities able to attract EVSE investment

North Charleston, South Carolina

North Charleston in Berkeley County, South Carolina, is situated in a new and growing US manufacturing corridor stretching from Michigan to Georgia.

The region houses many electric vehicle supply equipment parts manufacturers, several EV assembly plants, and is where hundreds of GWh a year of battery cell production capacity will be built in the upcoming years.

Berkeley County is also home to the newly announced plant of Redwood Materials. The plant will recycle, refine, and manufacture anode and cathode components. More than 1,500 jobs will be created and $3.5bn is set to be invested in the greater North Charleston area.

Volvo is hiring 1,300 additional workers at its assembly plant northwest of North Charleston to produce its new fully electric SUV model – the EX90.

Minden, Nevada

Minden is a popular submarket of the Reno, Nevada, metropolitan area where Tesla recently was awarded more than $330m in tax incentives for the company’s expansion of its sprawling EV Gigafactory northeast of Minden, including the construction of a massive, new semi-electric truck factory.

PepsiCo plans to roll out 100 Tesla Semis in 2023 first in California where they are fully operational driving a 400-mile radius delivering PepsiCo products for its Frito-Lay unit.

In addition to PepsiCo, United Parcel Service and food delivery company Sysco Corp have also reserved the new Telsa Semis.

Chattanooga, Tennessee

Thanks to $9.2m in general funding, Chattanooga will soon be home to the nation’s largest electric vehicle living testbed.

The idea, proposed by local officials and scientists at the University of Tennessee at Chattanooga, will let EV owners find charging stations customised to their needs. This works based on a system that recognises the charge level of individual electric vehicles, volume and pace of traffic, and electric grid power demand.

Volkswagen is also launching production of its new all-electric ID.4 SUV. The Chattanooga plant employs around 4,700 people, including 1,000 new hires brought on specifically for its new EV line.

A detailed look into EVSE costs

Greater focus on comparative operating cost structures in corporate relocation decisions has been driven by historic levels of inflation, new corporate tax hikes, and recessionary headwinds. This is especially prevalent in the electric vehicle industry, where generally, a new electric car costs around $10,000 to $20,000 more than a traditional gasoline car.

Many companies in the electric vehicle supply equipment industry are concluding that improving the bottom line on the cost side of the ledger will be far easier than on the revenue side in 2023.

Cost differentials between an acceptable EVSE industry site and an optimum location can be substantial even within a given US region.

Total annual operating cost ranking

The table shows the ranking of all 30 surveyed electric vehicle supply equipment industry locations.

The Boyd analysis focuses on key operating cost elements, including labour, taxes, real estate, construction, and utilities, and is scaled to a 150,000 square-foot EVSE manufacturing plant employing 500 hourly workers. These factors are considered to be most pivotal within the corporate site selection process.