TwistR Energy, a pioneer in supersonic cryogenic gas processing, teams up with TriGen Energy to decarbonise the industry.

Since 1999, TwistR Energy has been at the forefront of gas processing technologies. Their latest projects are now applied to help fight climate change. They do this with decarbonisation technology, namely, supersonic cryogenic gas processing.

These technologies offer a method of gas processing that can reduce or even eliminate emissions while providing sustainable and profitable gas production for energy purposes, significantly cleaning the industry.

TwistR Energy: Making cryogenic gas processing easy and sustainable

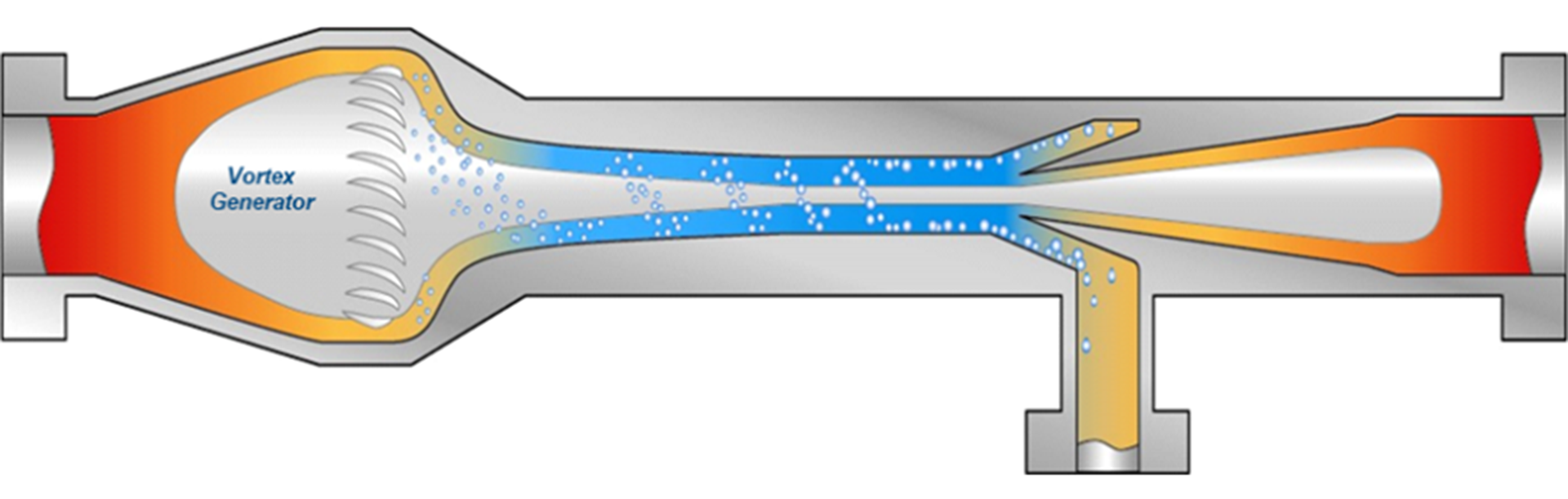

TwistR Energy is at the forefront of innovative gas processing technologies, offering solutions that blend supersonic cooling with high-G swirl technology. This proprietary approach allows for efficient deep dew-pointing and dehydration of gases, utilising compact units that are reliable and devoid of moving parts and chemicals.

The technology was proven over thousands of operational hours in both onshore and offshore settings, yielding significant advantages over traditional gas processing methods involving Joule-Thompson valves, Turbo Expanders, or chemicals.

Key benefits of the technology:

- Elimination of chemicals, sidestepping the need for regeneration equipment, storage, and logistical expenses;

- Our system’s low weight, small footprint, and modular design make it especially suitable for offshore installations and for enhancing and upgrading existing plants;

- Exceptionally low maintenance and operational costs, along with straightforward integration into facilities geared for unmanned operations; and

- Enhanced reliability and availability, leading to superior asset economics.

CO₂ bulk separation: Advancing the greenhouse gas reduction agenda

Utilising the deep cooling and high G-forces generated within a TwistR tube, our technology enables the collection of hydrate/CO₂ crystals at low temperatures. These are then converted into liquid form in a special crystalliser unit, marking a significant step forward in CO₂ separation efficiency.

Our CO₂ bulk separation unit has been successfully tested by a leading international oil company, achieving an 80% reduction of incoming CO₂ volumes in a natural gas stream. This process not only conserves energy but also streamlines system design by enabling CO₂ to be pumped rather than compressed. TwistR is actively expanding its cryogenic and supersonic processing capabilities for enhanced CO₂ management in terminals and transport systems.

Integrating with TriGen Energy for comprehensive decarbonisation solutions

TwistR Energy’s recent integration into the TriGen Energy portfolio underscores our commitment to holistic decarbonisation efforts. TriGen Energy is active in developing decarbonisation solutions through oxy-fuel combustion. TwistR’s suite of gas/CO₂ processing technologies enhances the efficiency of decarbonisation solutions by pre- or post-treating the CO₂-containing gases from TriGen and other chemical and CCUS plants.

This integrated approach not only increases the efficiency of the plant but also substantially reduces the overall cost of decarbonisation solutions.

Supporting our clients through innovation

We offer a comprehensive suite of services, including system design, optimisation, construction, commissioning, and operational support. Our proactive engagement in the early stages of project development ensures that our solutions are tailored to meet each client’s specific requirements throughout the project’s lifecycle.

We are keen to seek collaborative arrangements with our clients, aiming to co-develop and refine solutions that offer unique and competitive advantages. Together, we can lead the way in developing efficient, cost-effective cryogenic gas processing technologies that address the critical challenge of decarbonisation.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.