The global shift towards cleaner and more sustainable energy sources is driving the need for dynamic and efficient power-to-X (PtX) systems.

The global shift towards cleaner and more sustainable energy sources is driving the need for dynamic and efficient power-to-X (PtX) systems. These systems play a pivotal role in converting surplus wind and solar power into high-value products. Among the various technologies available, solid oxide electrolysis (SOE) technology boasts the highest energy conversion efficiency.

However, there’s a significant challenge that hinders its widespread adoption: the operation of SOE systems at part-load conditions, which means running below their thermo-neutral potential. This mode of operation introduces temperature variations that can lead to thermomechanical stress. Combined with actual lifetime, these factors have impeded the commercialisation of SOE technology.

Dynelectro: Paving the way for a greener future

Dynelectro, a pioneering company founded in 2018, has faced these challenges head-on. In just five years, Dynelectro has grown from its humble beginnings to a team of 15 dedicated colleagues. This rapid growth has brought its own set of difficulties, as the company navigates the complex landscape of green energy innovation.

Today, we’re thrilled to introduce a groundbreaking operating method that addresses these issues, offering a promising pathway towards more efficient and long-lasting PtX systems. This innovative approach is referred to as AC:DC operation.

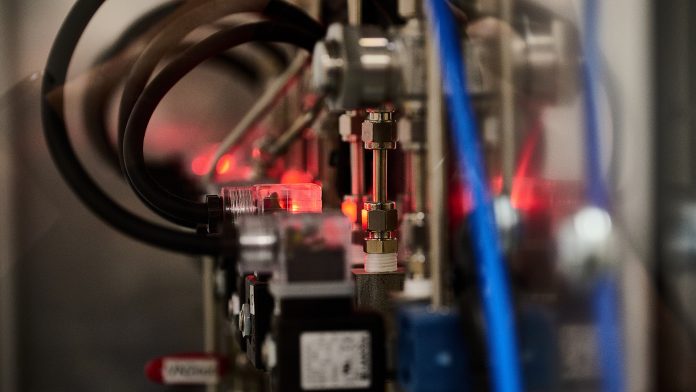

AC:DC operation works by rapidly switching between two modes — electrolysis and brief pulses in fuel cell mode — several times per second. This seamless transition maintains a consistent temperature profile across SOE stacks, preventing temperature fluctuations during the short switching periods. This method effectively mitigates thermomechanical stress and enhances the durability and performance of SOE systems.

Results of AC:DC operation

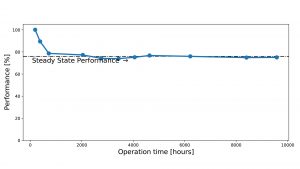

To provide real-world insights, we present the results of an ongoing year-long test involving a G8 stack provided by SolydEra with a nominal power of 4.5 kW in electrolysis mode. SolydEra is a key world player in the market of solid oxide cells, stacks, and solutions, with the largest annual production capacity in Europe. Its solid oxide technology has a proven track record and delivers best-in-class performance and durability in both fuel cell and electrolysis mode.

SolydEra has research & development and industrial manufacturing facilities in Italy, Switzerland, and Australia. Its headquarters is in Trentino Alto Adige, Italy. Dynelectro has engineering, research & development and production testing facilities in Denmark.

What’s intriguing is that we’ve observed a reduction in the degradation rate of the stack during this test. This reduction is believed to be linked to the desorption of impurities that would otherwise absorb and agglomerate on the active three-phase boundaries of the electrodes.

Moreover, we delve into the potential of AC:DC operation to enable dynamic operation in large SOE systems, addressing the unique challenges faced by power-to-X developers. This innovation holds the key to furthering the development and commercialisation of PtX technology, making it an even more valuable asset in our quest for a sustainable and greener future.

Join us on this journey as we simplify the path to a greener future with innovative energy solutions. Together, we can pave the way for a cleaner and more sustainable world, overcoming the challenges faced by power-to-X developers as we work towards a brighter tomorrow.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.