Biopolymers made of hemp oil form a versatile platform for high-performance plastics with benign degradation products.

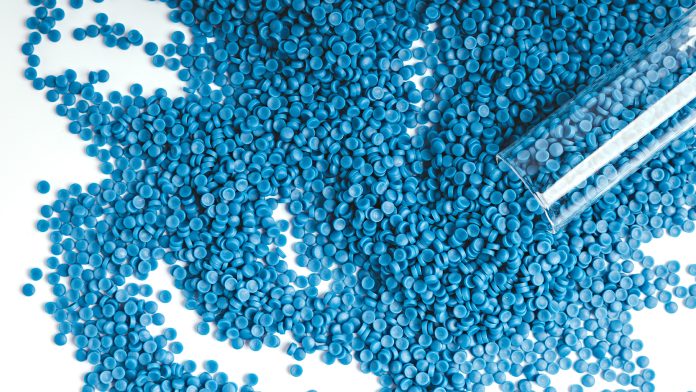

Polymers derived from biological sources have the potential to form benign components as they decompose in the environment or in our bodies. However, their market adoption has been hindered by mechanical and electrical properties that are lower than those of conventional polymers. A new class of biopolymers invented at the University of Connecticut uses hemp oil as the primary component, providing a wide range of exceptional properties.

A team including researchers from Purdue University, the University of Connecticut, and Rensselaer Polytechnic Institute have received a $3m Future Manufacturing Grant from the National Science Foundation to understand the range of properties that can be achieved with hemp-based polymers and develop the know-how to enable their adoption in manufacturing processes. The technology is being commercialized by PolyC Plastics and Composites, a company started by the research team.

Chemical diversity of hemp oil enables a wide range of properties

Hemp oil consists of more than 20 different chemical structures of oils. Mixing these oils in different ratios produces polymers with diverse properties that range from soft and sticky medical adhesives to stiff materials that can tolerate high temperatures, useful for printed electronics.

Hemp oil is being investigated for its potential medicinal benefits, which are based on its antioxidant and anti-inflammatory properties. The hemp-based polymers also retain these properties, which are expected to be highly beneficial for materials that are in contact with the body (e.g. wearable devices, catheters) and devices that can be implanted inside the body (e.g. stents).

These same antioxidant properties make the polymers useful for slowing down the degradation of metals like copper that are used in conventional electronics. Degradable metals such as magnesium and zinc are even more susceptible to oxidation than copper. One of the first applications pursued by the research team is printed electronics. The printed electronics industry is growing at about 10-20% per year. However, electronic waste is already a problem and is one of the most challenging waste streams to dispose of. The team is in the process of developing a set of structural and electronic inks to create printed electronics that will be easier to recycle and will have less damaging environmental impacts if improperly disposed of.

Environmental benefits of hemp as a feedstock

As a feedstock, hemp has numerous benefits. It is the fastest-growing plant in North America, making it an effective carbon sink. Hemp is used as a cover crop that can restore soil quality, but it can also grow in many environments, including mountainous areas that may not be suitable for food crops. Lastly, all parts of the hemp plant are useful: the seed proteins can be used for animal feed, and the fibres can be used for building materials such as insulation, which is already being adopted in Europe and has been gaining traction in the United States. As the hemp industry grows in the United States, the increased supply chains are expected to increase the availability of hemp oil and reduce the price of the polymers.

Production and degradation

The hemp-based polymers are produced using a simple process that is used to produce other commodity polymers like PET (the type of plastic used to make water bottles). The hemp oil monomers are linked together by removing water from the mixture of reactants to create the final solid polymers. By adding water back into the system, the polymers degrade back into their monomers over several months or years. Although hemp-based polymers are produced using a method similar to PET, PET is not degradable. The rate at which the polymers degrade is important for their applications. Polymers for short-term use, such as packaging, may need to only last for several weeks. Polymers for printed circuit boards may need to last for several years, while polymers for structural components need to last for decades. Through the NSF funding, the team will design polymers with different degradation times by varying the combinations of hemp oils.

Increasing evidence shows the prevalence and dangers of microplastics. While recycling approaches are promising, some disposal of waste in the environment is unavoidable. Polymers that degrade back to monomers within a controlled timeline will provide a potential solution to limit the proliferation of microplastics.

Please note, this article will also appear in the 20th edition of our quarterly publication.