Researchers at Penn State have experimented with laser-induced graphene designs to develop advanced flexible electronics for wearable health devices.

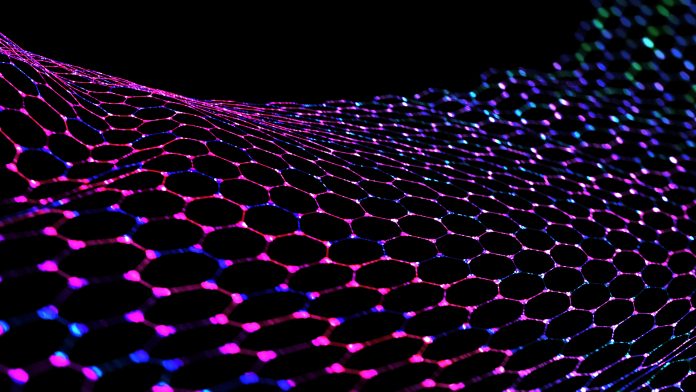

Graphene is comprised of hexagonally arranged carbon atoms in a single layer, thus making this two-dimensional material the thinnest material known to man. As well as being so thin, graphene is incredibly strong and has superior pliability and high conductivity. It is these unique qualities that mean graphite offers the potential to advance flexible electronics.

Now, a collaboration headed by Huanyu (Larry) Cheng from Penn State’s Department of Engineering Science and Mechanics (ESM), has published two novel studies that may inform research and development efforts for future motion detection, tactile sensing and health monitoring devices.

The research findings have been published in SCIENCE CHINA Technological Sciences.

Impact of laser processing on graphene form and function

Various materials can be converted into carbon in order to generate graphene through laser radiation. Known as laser-induced graphene (LIG), the material formed can contain specific properties that are determined by the original material.

The researchers decided to experiment with this process. Samples of polyimide, a type of plastic, were irradiated through laser scanning. The team varied the power, scanning speed, number of passes and density of scanning lines.

“We wanted to look at how different parameters of the laser processing process create different nanostructures,” Cheng said. “Varying the power allowed us to create LIG either in a fibre or foam structure.”

The team discovered that lower power levels, between approximately 7.2 watts and nine watts, led to the development of a porous foam with many ultrafine layers. This laser-induced graphene foam displayed electrical conductivity and a reasonable resistance to heat damage, both of which are useful properties for components of electronic devices.

By raising the power from around nine watts to 12.6 watts, the researchers found that this shifted the LIG formation pattern from foam to bundles of small fibres. These bundles grew bigger in diameter with increased laser power, while higher power promoted the web-like growth of a fibre network. The fibrous structure revealed better electrical conductivity than the foam. According to Cheng, this enhanced performance combined with the fibre’s form may open possibilities for sensing devices.

“In general, this is a conductive framework we can use to construct other components,” Cheng explained. “As long as the fibre is conductive, we can use it as a scaffold and do a lot of subsequent modifications on the surface to enable a number of sensors, such as a glucose sensor on the skin or an infection detector for wounds.”

By adjusting the laser scanning speed, density and passes for the laser-induced graphene formed at different powers, the conductivity and subsequent performance were also influenced. More laser exposure led to greater conductivity, but ultimately fell as a result of excess carbonisation from burning.

Low-cost laser-induced graphene sensor

Utilising their first study as a foundation, the researchers designed, fabricated and tested a flexible LIG pressor sensor.

“Pressure sensors are very important,” Cheng said. “We can use them not only in households and manufacturing but also on the skin surface to measure lots of signals from the human body, like the pulse. They can also be used at the human-machine interface to enhance performance of prosthetic limbs or monitor their attachment points.”

The researchers experimented with two different designs. To begin, they sandwiched a thin laser-induced graphene foam layer between two polyimide layers comprising copper electrodes. When pressure was applied, the LIG generated electricity.

The voids in the foam decreased the number of pathways for electricity to travel, making it easier to localise the pressure source, and seemed to enhance sensitivity to delicate touches.

When attached to the back of the hand or the finger, this design was able to identify bending and stretching hand movements, on top of the characteristic percussion, tidal and diastolic waves of the heartbeat. According to Cheng, it is possible to combine this pulse reading with an electrocardiogram reading to produce blood pressure measurements without a cuff.

For the second design, the team integrated nanoparticles into the laser-induced foam. These small spheres of molybdenum disulfide – a semiconductor that behaves as a conductor and an insulator – increased the foam’s sensitivity and resistance to physical forces. The design was also resistant to continual use, indicating almost indistinguishable performance before and after nearly 10,000 uses.

According to Cheng, both designs were cost-effective and permitted simple data acquisition.

Going forward, the team will continue to investigate the designs as standalone devices for health monitoring or in tandem with other extant equipment.