American Battery Technology Company takes another step toward a combustion-free future by securing a $2m contract for a lithium-ion battery recycling commercial demonstration.

Although the benefits, drawbacks, and projections regarding the future of EVs dominate the public conversation, little attention is paid to what will happen to the components in these vehicles — their batteries in particular — when they reach the end of their lifecycle. Because lithium, an essential component in the batteries that power these vehicles, is a finite resource, the lack of public discussion considering the future of its use and sourcing is concerning. However, just because we do not hear about these factors does not mean they are not being addressed in the background by industry experts. The United States Battery Consortium, in collaboration with the United States Department of Energy, has awarded the American Battery Technology Company (ABTC) and partners BASF and C4V a grant award worth over $2m to demonstrate that battery grade metals can be manufactured from recycled materials at lower cost, lower environmental impact, and with higher domestic US-sourced content than conventional virgin sourced metals.

And if 2020 and the years following have taught us anything, it is that there is little about the future that is guaranteed. However, we can most likely claim as sure that the future of driving is overwhelmingly electric. Not only did California and New York state regulations introduced in 2021 state that all vehicles sold past 2035 must be electric, but the shift is also incentivised by the environmental and cost-saving benefits of electric vehicles (EVs), including decreased gas usage and a reduced need for regular and long-term maintenance.

The vision for lithium-ion battery recycling

While this is a win for ABTC, how exactly will that $2m solve our future issues of possible lithium shortages and the disposal of lithium-ion batteries currently used in various applications?

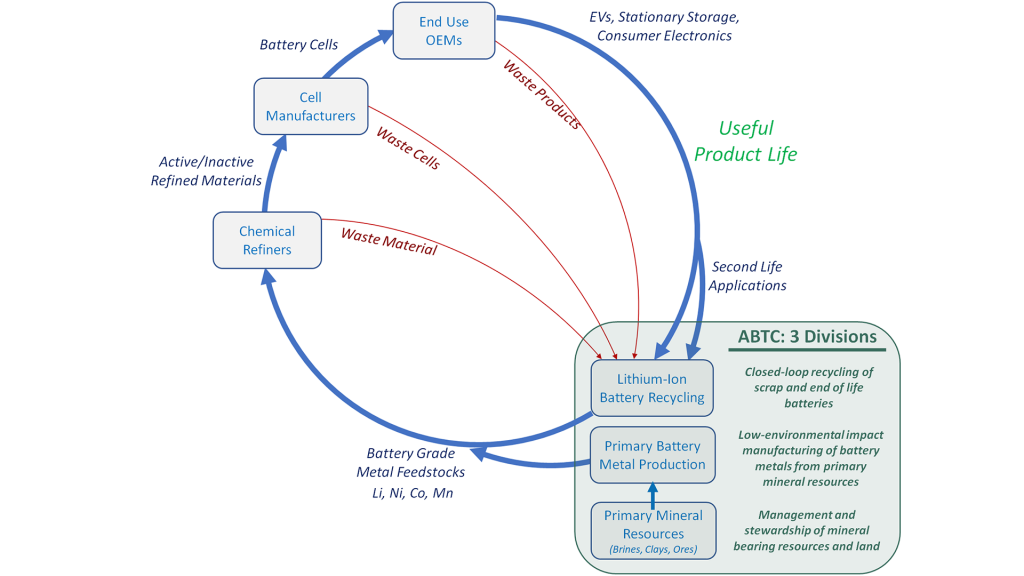

The project team aims to utilise a circular economy to recycle these batteries, solving the issue of recycling and remanufacturing these valuable and finite compounds. By doing so, this project will demonstrate a complete domestic supply chain capable of manufacturing new lithium-ion batteries from recycled materials at a lower cost and with a lower environmental impact while using higher ratios of domestically-sourced materials than new-resource manufacturing.

If successful, the project will considerably impact the future of lithium-ion battery recycling in the United States. Demand for these batteries is insatiable. As more and more people use technology that relies on li-ion batteries for EVs, smartphones, stationary grid power storage systems, and solar power energy systems, the pressure to produce new units is sure to increase. Unfortunately, the US has not kept pace with the infrastructure or manufacturing capabilities required to compete with other countries in battery manufacturing. This has presented three primary challenges for ABTC to overcome the security of supply, which refers to the availability of valuable compounds including lithium and manganese, cost of supply, which refers to the mounting costs associated with these compounds, and environmental impact of supply, which refers to the detrimental environmental impacts of mining and shipping these compounds to manufacturing facilities, often internationally.

A closed economy, in theory, can address all three challenges. Through utilising new processes, ABTC aims to ensure the maximum amount of the necessary compounds are reclaimed. This means if old batteries are available, then the manufacture of new batteries is possible and at a much lower cost, which addresses both the security and cost of supply. Because processes used to reclaim these materials will lessen the demand for the mining of virgin resources, the environmental impact of supply should also be addressed. However, the key challenge in addressing this factor will be ensuring the amount of energy consumed, and pollution output in reclaiming materials will not surpass the environmental costs of mining and shipping virgin materials. Considering only eight global supply chains are responsible for more than 50% of yearly global emissions, reducing environmental impact is feasible.

So, what would a closed-loop, circular economy look like in action? The graphic above should give you an idea.

If their concept proves to be viable, the United States will not only be a step closer to this cleaner future but will also cement themselves as an example of how closed-loop supply chains can work in reducing cost and pollution while also addressing material demands.

Please note, this article will also appear in the ninth edition of our quarterly publication.