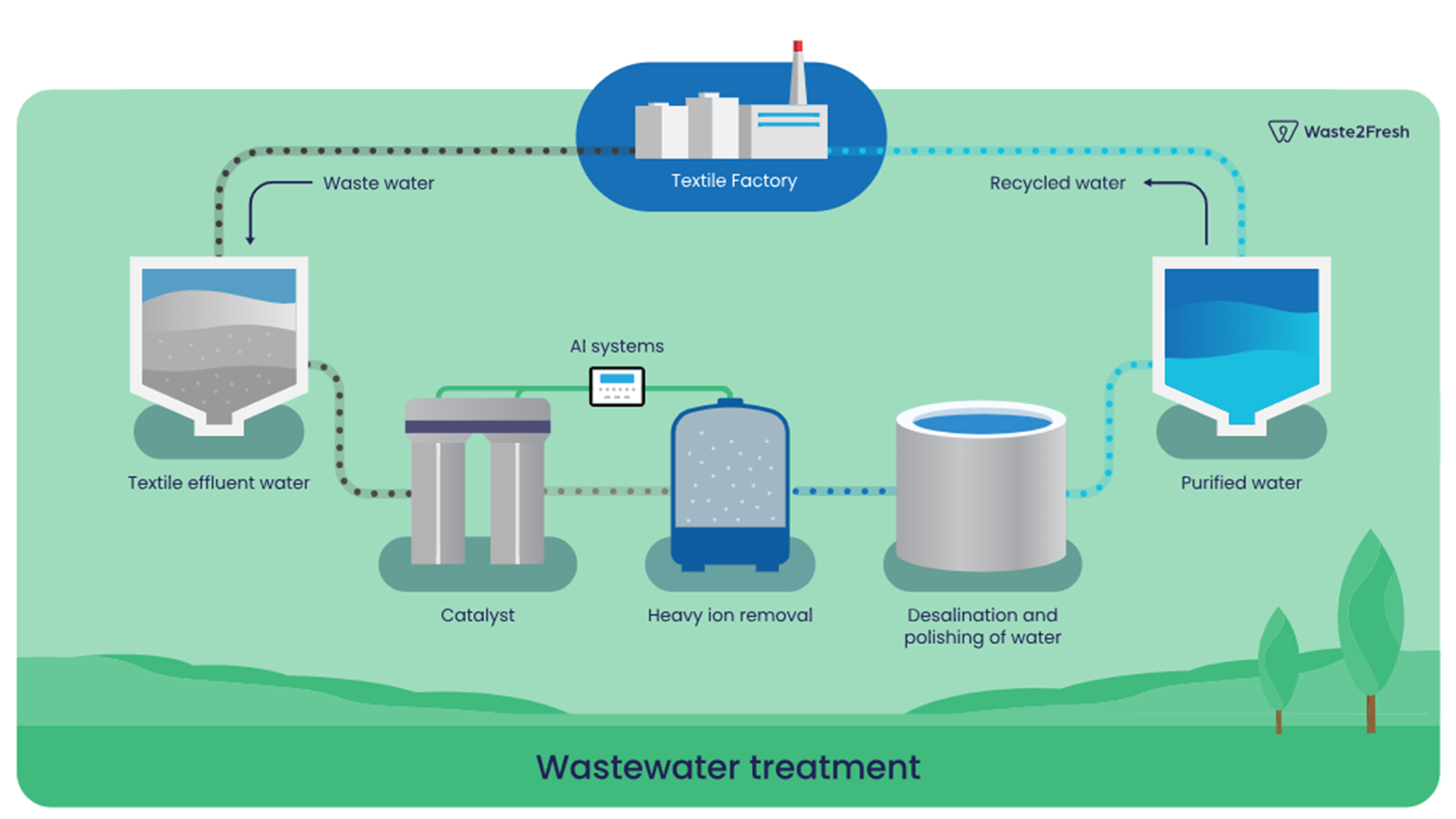

Waste2Fresh is a project that is utilising multiple innovations to solve the problems of denim wastewater contamination worldwide.

Textile dyeing and treatment is responsible for 20% of water contamination. Large denim factories use large amounts of water for their dyeing and washing processes, (to produce the faded look,) and then discharge the processed contaminated water into water courses. This leads to an increase in water stress as the water used for these processes reduces water availability for the local population. The contamination of water courses leads to the destruction of natural habitats in rivers and the sea and increased toxicity of water available to the local population.

Waste2Fresh: A sustainable solution

Waste2Fresh is a project funded by the EU to focus on this problem and to produce a working demonstrator combining new technologies which efficiently and cost-effectively treat and recycle the water in a denim factory in Turkey.

The wastewater is taken directly from the process machines. It is treated quickly using catalytic processes, photocatalytic processes, and membrane separation to remove the colour and associated harmful effects without producing sludge. This means that little space is needed, leading to more of the factory site being available for production.

The new material developed to degrade the dyes is a bio-composite of nanostructured material grown without the need for fertiliser, pesticides, or irrigation. The spent products can be regenerated and are biodegradable at the end of life.

Circular economy principles in action

The project design has used circular economy principles, life cycle analysis (LCA), and life cycle costing analysis (LCCA) to underpin the work to create a totally environmentally sustainable system. Solar concentrator technology that uses natural sunlight to degrade the organics, with LEDs performing the same function during night-time hours, has been deployed.

To optimise and control the process, new sensors have been developed that can measure levels of wastewater contamination and ensure that the treatment deployed can achieve standards for recycling within the factory and also achieve zero discharge of hazardous chemicals (ZDHC) standards for discharge and external use.

The Waste2Fresh project takes a focused approach, understanding everything in the recipe and process and utilising technology to treat each part effectively. Within the project, we remove metal ions and salt using a separation, removal and upgrade strategy. We provide and store our own energy. Rainwater harvesting is utilised to supplement the water loss in the closed-loop recycling system to ensure that enough water remains in the system for use.

Stakeholders and global alignment

There are many stakeholders that are interested in having a solution to the issue of industrial wastewater contamination. In the case of denim, these are the brands selling the jeans, the government authorities in charge of environmental policy and regulation, the local communities, and the dyers and wash plants. In places like India, 30% of textile factories do no treatment and those that do only do remedial treatment, which may be costly and produce harmful sludge. All stakeholders want to see a solution, and now that the partners of Waste2Fresh have pioneered a solution, alignment is needed globally to stop textile dye pollution.

Waste2Fresh has enabled the different technologies to work together to provide a solution and to ensure compatibility when working together. They can be provided as individual solutions depending on the customer’s requirements. Where Community Effluent Treatment Plants (CETP) are used, some of the technology can be deployed to remove the colour and associated harmful effects from the textile factory water before entering the treatment facility. Those areas with an arsenic problem can benefit from removal and in-line sensors to detect levels.

Tackling textile factory wastewater

The amount of wastewater from textile factories worldwide is more than the volume of an Olympic swimming pool a second. This is a key area to tackle to reduce contamination and reduce water scarcity, and the innovative technology used in the Waste2Fresh project promises to provide a major contribution to society.

Whether it be on the beautiful islands of Mauritius or the water courses of Bangladesh, contamination from textile factories causes a major problem. It is time to embrace the solution and roll it out across the sector. Nanofique Ltd are leading the provision, and they will assist those wishing to provide local solutions. Richard Burke from Nanofique Limited said: “Our mission is to end textile dye pollution, and to provide the technology needed to achieve that.”

Although the initial focus has been on the denim sector, the technology has been used to provide solutions for other textile companies. It can work well for large denim factories as well as at the other end of the scale, such as village bespoke dyers.

We look forward to seeing how Waste2Fresh can revolutionise industrial wastewater treatment and provide a pathway for other innovative environmental solution deployments.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.