Dr Mark Powell, CEO of Marineholmen RASLab, discusses how wastewater and sludge valorisation from recirculating aquaculture systems can lead to a more sustainable future.

Land-based farming of fish is promoted as a sustainable future for intensive aquaculture systems based largely upon its reduced footprint, low water use, controlled environmental conditions, and low impacts of parasites and disease. This, however, comes at a cost, which is primarily energy use that drives the cost of production.

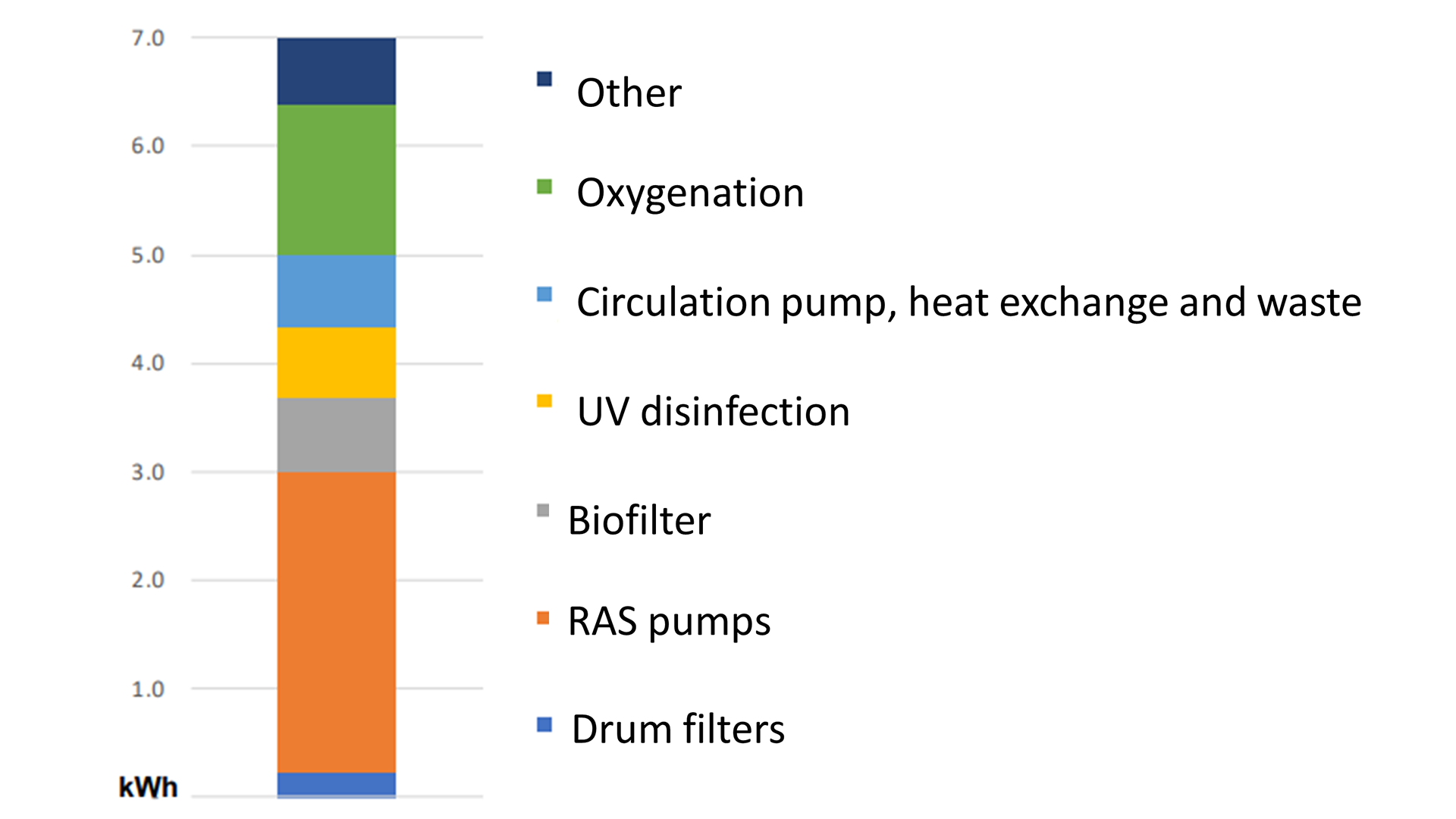

Estimates for the land-based production of Atlantic salmon in recirculating aquaculture systems (RAS) have been suggested to be approximately 7 kWh/kg of fish produced with an estimated carbon footprint of 0.114 kg CO2 equivalents/kWh. This value may vary significantly with different species and depending on how intensive the production is. Nonetheless, RAS farming is not cheap, but the benefits are high when producing species with a high market value.

Nitrate concentration in wastewater

The main outputs in RAS aquaculture, besides CO2 (which is typically degassed from the RAS system) and fish biomass, are highly nutrient-rich wastewater and sludge. The former is enriched with high levels of nitrate – the end point of nitrification. It is typically the nitrate concentration that ultimately dictates the rate of water exchange in an intensive RAS aquaculture system, assuming no active denitrification process is being employed.

In systems employing such ‘zero water exchange’, nitrate is anaerobically converted to N2 gas, which reduces the need for water exchange in the RAS system. Although a relatively recent commercial development, these systems are becoming more commonplace. In a conventional RAS system, nitrate levels can be varied, although levels of 150 mg/L or more are not uncommon. This represents a highly nutrient-enriched wastewater that can be further utilised.

More conventional approaches have seen freshwater RAS wastewater being used in either open-circuit (where water is used to horticulture then discharged) or closed-circuit (where water is recirculated into the fish production process) aquaponics. Whereby plants (typically under horticultural conditions such as leafy vegetables or herbs) are grown using the nitrate-enriched water. Brackish water poses a challenge with increased levels of salt in the wastewater. The culture of salt-tolerant plants or macroalgae offer a solution which is currently under development.

Another alternative is the culture of microalgae in photobioreactors associated with RAS aquaculture systems. At Marineholmen RASLab, the testing and prototyping of combined RAS-based Atlantic salmon smolt production, in combination with microalgal production, is being investigated with its research partner, NORCE.

Sludge

The solid waste component (made up largely of fish faecal matter and uneaten feed) is referred to as ‘sludge’. Conventionally, this waste is collected either from sedimentation and/or from a drum filter or similar filtration device and is discharged from the RAS aquaculture system to be collected in a storage tank from where it is disposed of. This material, which is high in energy content and contains large amounts of undigested and unabsorbed phosphorous, is a valuable resource for further processing.

Traditionally, the sludge may have been used for soil enrichment or fertiliser for agricultural purposes. However, more recently, it is seen as having potential to produce biogas. In collaboration with NORCE, Clara Venture Labs and the University of Bergen, RASLab, in a project known as the ‘Sludge Appraisal team – Developing a sUstainable value chain from tank to product’ (Slam-Dunk), has been exploring the production of biogas through the fermentation of sludge and bacterial cultivation, as well as the pyrolysis of the solid material using microwaves to produce a gas (syngas).

The resultant gas from these processes can then be used for energy or refined for use in fuel cells. The results suggest that different sludge composition from different stages of Atlantic salmon production yield different potential products for the further development of bio-synthetic gas and potential products. It is, however, anticipated that further development of these processes will lead to the valorisation of the waste products and thus increase the net sustainability of the entire Atlantic salmon production value chain.

A sustainable future for aquaculture systems

Although in its infancy, the further development of waste streams as valuable resources in aquaculture systems points to a more sustainable future and maximises the net value to be gained from land-based fish farming, ultimately increasing the net value per unit energy input into intensive fish production.

The concept of using fish waste for potentially producing fish feed for further generations, through either bacterial biomass production or through algae or other protein-based production (such as insect larvae), is another exciting possibility. However, this is currently fraught with legislative challenges until the safety of these potential feed ingredients are proven. However, once overcome, the circularisation of aquaculture will highlight the potential for this blue economy. In the meantime, microalgal production and bio-synthetic gas production offer significant solutions to the nutrient-rich wastes from land-based farming – another way in which Marineholmen RASLab is ‘innovating the future of aquaculture’.

Please note, this article will also appear in the fourteenth edition of our quarterly publication.