Graphene technology company Zentek Ltd has made major progress with its ZenARMOR corrosion protection technology, having been awarded a grant to test its products in military-grade systems.

Headquartered in Canada, Zentek Ltd is a graphene and corrosion technology development and commercialisation company dedicated to researching, developing, and commercialising novel graphene-based products to give its commercial partners a competitive advantage by making their products better, safer, and greener. Alongside its partners, Zentek works to create intellectual property by utilising nanotechnology to enhance existing products and develop solutions that improve people’s lives.

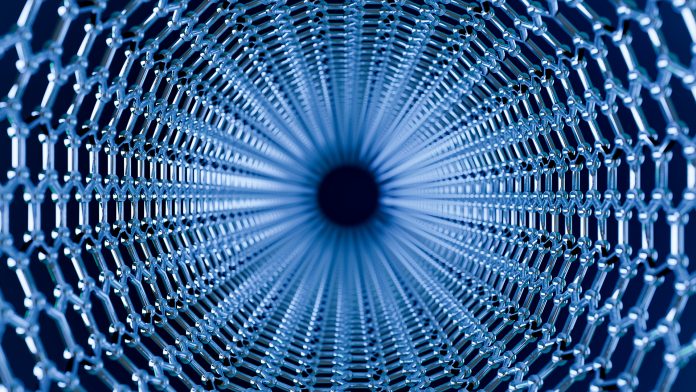

All about graphene

Zentek’s focus material, graphene, is the world’s thinnest, strongest, and most electrical and thermal conductive material. Graphene is 200 times stronger than steel and one millionth the thickness of human hair. Graphene has an extremely high surface area-to-mass ratio – each gram of graphene has a surface area of more than 2,600 square metres. The properties of graphene mean that its potential is immense. It can be added to plastics, metals, and many other materials to make them stronger, lighter, more durable, and more conductive. Its extremely high capacity and electron mobility also enables graphene to greatly advance energy storage and microchip technology.

Amongst its innovations, Zentek’s patented ZenGUARD™ coating has been proven to have 99% antimicrobial activity and to significantly increase the bacterial and viral filtration efficiency of both surgical masks and HVAC systems.

ZenARMOR corrosion protection technology

Zentek has also created the patent-pending ZenARMOR™ technology platform, which is focused on corrosion protection applications. Corrosion is a costly issue that impacts many industries, including naval and marine infrastructures, bridges, buildings, and pipelines. To help combat this problem, corrosion protective coatings can extend the life of existing infrastructure and equipment.

Over the last two years, Zentek has developed a new corrosion protection technology based on functionalised graphene oxide. ZenARMOR offers superior performance, self-healing properties, and a potential environmental advantage due to having a very low loading of active ingredients compared to other corrosion protection products on the market.

Recently, Zentek has been awarded a research and development (R&D) grant through Innovative Solutions Canada (ISC) to test ZenARMOR nano-pigment in military-grade, chromate-free, corrosion protection aerospace paint systems. The testing will be conducted under the supervision of Dr Qi Yang and Dr Naiheng Song, Research Officers at the National Research Council of Canada (NRC) Aerospace Research Centre’s Aerospace Manufacturing Technologies Centre (AMTC).

The testing will aim to:

- Confirm that ZenARMOR meets the required aviation standards;

- Optimise the concentration of ZenARMOR in aviation paint systems; and

- Compare the corrosion protection of ZenARMOR to chromate-based paint systems.

Speaking on the announcement, Greg Fenton, CEO of Zentek, said: “We are grateful to have been selected for this ISC-TS by our partners at the National Research Council of Canada, which we believe is an important step in continuing to prove out the efficacy of our ZenARMOR technology in corrosion protection paints. This is an area that has taken on heightened importance due to the high cost of corrosion. This award confirms the Government of Canada’s commitment to working with innovative domestic companies to help address this challenge.

“Importantly, we see this as a potential precursor to commercialise our corrosion protection technology, not only within the Canadian Government, but with other interested parties as well.”

Users of corrosion protection paint systems and companies producing corrosion protection coatings which are interested in incorporating ZenARMOR into their existing solutions can contact Ryan Shacklock, VP, Strategy & Business Development at Zentek, at rshacklock@zentek.com

Please note, this article will also appear in the fifteenth edition of our quarterly publication.